Since 1993 Copyright Notice

My (never complete...) Tube Tester Collection

When you are here, you are probably are interested in tube testers in some way. Same as me! I remember very well how I threw away a shoe box full of used ECC81, many Mullard and Philips, using a defective tester (in 1988) and they tested all in the '?' range. I didn't have much knowledge about tube testers. I thought an old tube tester is like an old multi meter. Not very accurate, but I only wanted to know of the tubes were good or bad. Later I learned, the old tester was indicating too low value for all tubes, and perhaps these tubes were all fine. More later, I learned that many unserviced vintage tube testers indicate complete false results, and nobody realizes that. It is amazing how these can fool the user with a false impression of accuracy, each in their own way. Perhaps it was used for many years like that, and the owner felt good about throwing those "too weak" tubes away, while they had only a very small sign of use. Or, vice versa, it tells you the tubes are "new" and they are intensively used. Very famous for this is, old 220V testers, today plugged into 238V, coming from 230V outlets. If you noticed perhaps the same tube is not testing the same always, that is because of randomly changing mains voltage today. So do not fool yourself, and set those old testers to 240V if they have the option. The same is with 115V vs 110V. Even when the difference is only 5%, a tube with a weak cathode, reacts very good to 5% more heater voltage. On top of that, anode voltage for testing, goes up 5% which has a very good effect on most tubes. So with a 110V tester, plugged into 115V mains, "just ok" tubes will test "very good".

Verify the functioning of an old multi meter is easy. There are always some references around. You can measure the mains voltage, batteries and of course known resistors, and you get a fair indication about it's condition. But with a tube tester, this is not so. What can people do? They plug a new tube in it, and it tests good. They take a bad tube, and tests bad. It seems to confirm the tester is ok. But would you have needed a tube tester for this? If you already knew the good tube was good, and the bad tube was bad, the tester is supposed to tell you "how much". It is just this which is Russian roulette with an unserviced tester.

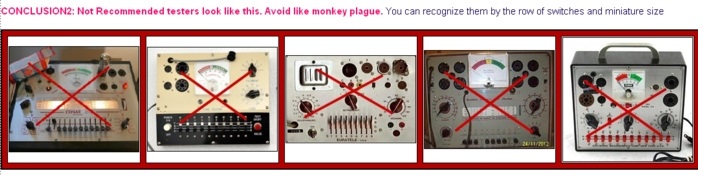

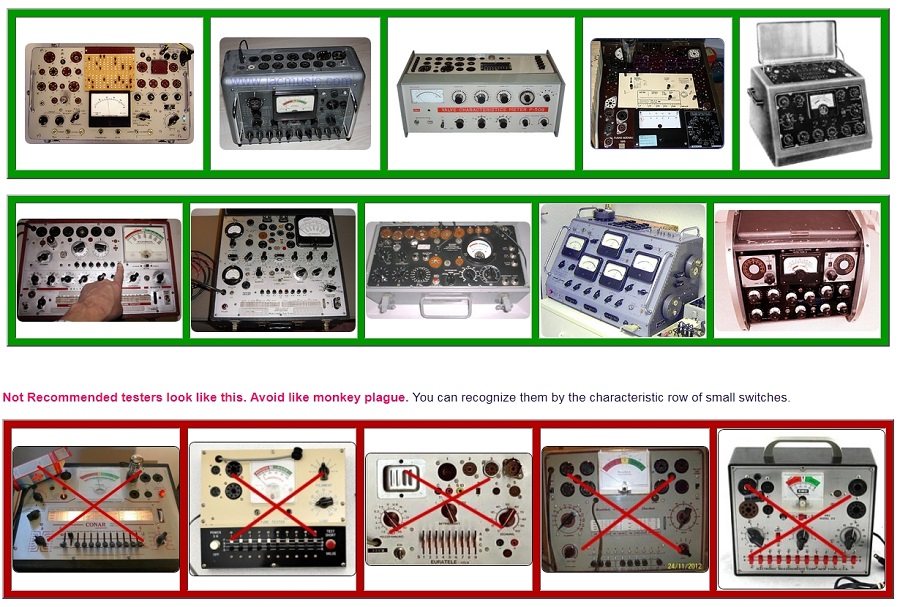

Also, think about this carefully: Some testers are large and heavy, and full of large transformers and electronics. Some others, when looking inside, surprise you with the transformer being so small you can hardly see it, and almost complete lack of electronic parts. The manufacturers, offering the more complex testers, and the buyers of those, must all have been pretty stupid, 70 years ago. Not knowing good tube testers can be build from almost nothing. I do not think this situation changed recently, and when I see how people pay easily 350 Euro on Ebay for silly, useless testers, I can say yes, nothing changed ever since. The really good ones cost only twice as much, and the price difference is the same as a quad of new tubes. But no, those cheap testers are bought preferably. With the same attitude, as people were fighting in the super market for toilet paper during the beginning of Covid19. There has always been an industry of tube testers, which were fakes already when they were made. Of course, the buyers found that out soon, and put those aside. That is why these look normally "as new" when you see them on Ebay. If you buy one, you will only be the next to put in aside soon. This will be described further down here, but first for the fun, try to answer those questions below. These questions are intended as eye openers, but it is really so as described there:

Which of the below was said by professionals?

- The tube is good, because the amplifier plays well on it. (check this answer)

- We use this circuit since 25 years, and it never went wrong. (check this answer)

- Electronic instruments are the glasses through which we see our products.(check this answer)

- We have done so much, for so long, with so little, we are now qualified to do anything with nothing. (check this answer)

When it comes to buying a tube tester on Ebay, there is often no quick alternative for this. But stay patient, and look carefully. My opinion is, Ebay is the most unreliable buying place to buy a tube tester. That is because there is very high demand for really good testers, and mainly supply of unverified or fully useless testers. I can not repeat often enough, what a terrible mess is sold there, to unknowing buyers. Recently, someone contacted me by email about a tester with a loose wire, asking me where it should be connected to. Though the tester worked fine. It appeared, the seller cut loose a wire from the shorts test circuit, to hide there was something wrong with that. So the tester indicated shorts for all tube electrodes but one. Chances the buyer would find out were low, because shorted tubes are rare. Yet they may catastrophically damage your tester, when you can not do the pre-testing for shorts. So the seller nicely got rid of a so called good tester, which he was unable to repair. This is just one example of many.

Over the years, this page has grown much larger as expected. Please note this: This website is a commercial one, meaning I live from it. I understand you probably have many questions, since you are reading this text because you are interested. Still I need to take care of orders first, so I cannot answer emails asking for free technical support. Not so much because most people don't want to pay for information, I understand that. It is just I don't HAVE the time to take care of this. So for any questions about a broken tester you bought on Ebay, or somewhere else, please discuss it with the seller, or post it on a forum. Here is the best advise I can give you, when you come to the conclusion you can't repair it: Just sell it again on Ebay and buy another one. The price difference between a good one and one with small errors is low, because there is always somebody who believes he can repair it. Or, buy a second one, compare them, and put all the good parts in the one you intend to keep. The bad one with the flaky parts, sell it honestly as such, and it may even sell for 50% of a good one. Things like that will result in a solution and not give you a head ache.

Finally, get yourself some reference tubes (we sell those) and compare your tester with tubes of known values.

Have fun reading!

READ THIS TEXT FROM 1958:

The point in question now is whether the emission or transconductance test is the best. This is determined in part by the circuit in which the tube is to be used, in case of an RF or IF amplifier tubes, the stage gain is proportional to the transconductance; for this the Gm test is the most important. In case if an output or power rectifier tube, it must be capable of supplying large amounts of current; here the emission test is the most important. From: Fine Points of Tube Testing. by William F. Burke, Consulting Editor, which appeared in the 1958 Test Equipment Manual. |

CONTENTS TABLE

- What tube tester do you need?

- Calibration set

- For Sale items

- How to test tubes, on various types of testers

- About accuracy and errorz

- Meter Protection

BUYING ADVICE, or why EBAY is no good place to buy a tube tester

BUYING ADVICE, or why EBAY is no good place to buy a tube tester - Tube Tester Collection. ANALOG. PART1

- Tube Tester Collection. ANALOG. PART2

- CENTRAD 752(N)

- CONAR(N)

- DIY(N)

- EICO666 connected to a digital curve tracer

- ELPO(N)

- General Radio

- FUNKE

- GRUNDIG

- HELIOWATT (CALL FOR HELP)

- HICKOK(N)

- KALIBR L3-3 Model from 1986

- NEUBERGER RPM370 and RPM375

- METRIX

- TEKTRONIX Curve Tracers

(N)

(N) - How to choose a Hickok Tester

- Tube Tester Collection-DIGITAL PART

- Amplitrex professional Digital tester

- BIAS King

- BITMATIC Digital tester

- CANOR professional Digital tester

- E-tracer (Ready PCB + DIY housing)

- ROETEST (Kit version)

- SOFIA. Vintage Digital Tester, runs under DOS

- uTracer ( Kit Version)

- Pulse testing vs full power testing

- Detailed Compare of digital testers

![]()

Ratings, at 'Conclusion' Part: See here

1) What tube tester do you need?

I receive this question many times be email. People have understood from this article, Ebay is not a good place to buy a tube tester, but they want buy a tester anyway. So the idea is often to buy a new made tester, and I am asked for advice. The question is then often like this: I have decided for an E-tracer or an Amplitrex, is it a good tester? To answer this, you need to define your 'must' and what is your 'want'.

Categories of Tube Testers

Roughly tube testers go into three categories:

- QUALITY TESTERS. The better ones are a combination of those. The Sofia tester, which is to my opinion the best tester ever made, it can do all three. When deciding what tube tester you need, It is very important top set your 'must' and 'want' accordingly.

- CURVE TRACERS. Strangely, the less people know about tubes, the more they want to have a curve tracer. They expect some kind of learning by doing, ending up in deriving tube quality from tube curves. Unfortunately this is fully impossible. You can only see from the curves of the tubes are good or bad. But when they are good, they may as well be 50% used up, or brand new. Tube curves are needed to design circuits, and you are totally lost when you think they are good for something else.

- PARAMETRIC TESTERS. Do you get random tubes on the bench, and want to know if they hold up to the data sheet values? Forget this, because there is no such thing as a data sheet value. Data sheets give only "average" data, without saying where good ends and bad begins. Only 1% of those specify those reject limits that you were interested in, and of course as you sure will know, such data is always specified in auto bias mode. So if your parametric tester can work in auto bias mode, and if you can select the auto bias resistors as by the data sheet, then you can do this. In all other cases you can use it for what you like, but not to compare a tube against a data sheet.

REAL QUALITY TESTERS. Sometimes called emission testers, but that is generally not what they are. So tubes are generally not tested at the limits of their emission, but with a much smaller load, and the "predicting" how that would work with a real load. Whereas Funke W19 really used 100%, and even exceeds that shortly for the tine of the test, depending on the tubes. That is professional. Hickok also does it quite good, in the terms of the result. Though they stay far below real (100%) emission. They use difficult to understand circuitry, and do not give any information whatsoever about what they test or how it's done. They give only the judgement on a good...bad meter scale. This is not so much what people like to hear, but a good Hickok knows better what is a strong tube, than an amateur with a parametric tester, trying to comparing measured values with acceptance levels which he invents on the spot by himself. So he ends up with some estimation of what the acceptance level is supposed to be, whereas the makers of the tubes never published that. So comparing a precision measurement with a self estimated maximum deviation of data sheet average values, is is just silly. And I am saying this carefully. Frankly, this is quite stupid. Yet I see it often, that people buy an expensive parametric tester, and get stuck in this situation. So your KT88 tests at 67,23mA. In the data sheet you read 80mA. Great. And now what to do? You don't know. But when it is nicely in the green zone of a calibrated Hickok, you have a better answer. Can you derive the same answer from this 67,23mA? If you think you can say this while the data sheet can not say this, you are producing what I like to say: Output without Input. (And if a tube produces output without input... what will you do with it...) This is what I like so much about a (good!) Quality Tester. No numbers, or curves which do not say what I want to know. They give only the answer in words like good or bad, but since that is all you get, it must be a professional one.

Good Quality Testers are big, heavy, and not cheap. Consider a Hickok or a Funke W19. These are the best. Or, the previous models: Hickock I-177 is perfect for older tubes. A Funke W18 is fine also, but much older, and cards may be bad condition. Few of the good ones are for sale, and you will also see W18 often very heavily used. W19 cost more but is a lot younger and generally good condition. The Hickoks are generally not good condition. They usually work when you buy them, but also they need a calibration, and check up. Which is extremely nasty if it's your first project. A really good one is worth 3x more than a bad one, and when it's really good, the reliability is hard to beat. An ideal beginner's tester is also Funke W19. Though is is not cheap, that is for good reason. It is strong, reliable, easy to repair, needs normally no calibration, and it is fool-proof to exceptional level, because everything is card programmed, and there is only one single knob of it. Besides a joy to use it, it never let me down, it has all sockets whatsoever and tests any crazy tube from 1920 until latest tubes from the 1980's.

FAKE QUALITY TESTERS. It's easy to produce a device which will move a needle, the better a tube is. But these are only helpful for a fool. Do not expect these to tell you more about the tube, than you already know yourself. When the tube is not working in your amplifier, the tester will say it is bad, or vice versa. And even less that that, because in the amplifier at least there was high voltage and high current. If there is some doubt, the tube will work good under THOSE conditions, do not believe such a tester can say anything useful, by testing all tubes with the same circuit, which is diode mode, 70 Volts AC on it, and a 2 Watt resistor as a load. The only variable is the setting potentiometer which only attenuates the meter movement. These are good at detecting a broken heater though, or loss of vacuum. Like when a TV service man needed to find quickly that dead tube in a series of 35 tubes unplugged from a none working color TV. From the days I repaired TV's myself, I remember this gives already a 50% change on a quick repair. This was the only intention for those. And for that they are really much better suited than having to carry a Hickok 539C around, or Funke W19. So they are mainly small, light weighted, few knobs, few sockets, and simple to use. They cost on Ebay only 1/3 of a real one. Many are for sale, and you will also see they are often hardly used. That is because the owner at some point found out they are useless indeed. Do not regard those beginner's tools, which you can learn something from.

This is important for beginners: Check these categories above here, and make your choice from there. Otherwise you may end up with a tester you will not like.

Accuracy

The big 'must' and 'want' category. Not always the most 'accurate' test data is better. It is so interesting to have a curve tracer, but when you can read 'weak' or 'strong', from the tube curves, you can do more than I can. The thing is, when tube curves look optically bad, it is far too late. Much before that, some better ways to measure would have helped you more. Tube curves are for constructing the working point, during amplifier design. Well and also for people who like technical stuff.

More about Parametric Testers

These are for people who know a lot about tubes, because parameters by itself only make sense in relation to each other, and not everybody truly understands that. So people often end up by declaring the average working point a 'must'. Knowing this is unreasonable, they allow 10% and call that reasonable. Some others say 20% or 30%, or they say 30% yes, but that is a used tube. This may perhaps be so. Or just as well perhaps be not so. Just look at this silly situation: They have an ultra precise precise parametric tester, and then need to estimate if the results are good or bad, and for that pick limits just randomly by themself. They would have been far better off, with a Quality Tester, which makes no mistakes in separating the good from the bad tubes.

Parametric testers are mainly used for tube matching, BUT that will only work when you know exactly how this is done yourself. Such testers will not touch the subject of Quality. Some exceptions exist, like the good old Sofia. Or the AVO Testers give parameters and quality at the same tine. Do not think you will get meaningful results quickly, from learning by doing.

More about Quality Testers.

And why you cannot replace such by a curve tracer

In simple words, a curve trace will tell you the curves, and a Quality Tester will tell you the quality. Judging tube quality from the curves, is only possible when the tube is excellent, or very bad. Anyone can do that. But be more precise for tubes in between, has always been the domain of the Quality Testers. The difficulty is when the curves are not average. Then, what? Good quality curves don't have to be average. In fact only 10% of new tubes have such average (bogey) values. Specially with used tubes, a curve tracer is the #1 source of mistakes. It has always been like this, that for quality testing, you need to use the tube in auto bias, and warm up the anode until working temperature. There never was any other way, apart from using the tube in diode mode, which is also very useful to find out quality. So any testing with fixed grid voltage is fun to do, and suggest precision if digitally presented, but conclusions about quality are in fact with elementary errors, and it becomes totally unserious. So when a normally good Quality Tester says the tubes are good, and a curve tracer says the tubes are bad, that is because you can't use it for that. All curve tracers I know of, use fixed grid voltage. I can show you many places in old literature, saying fixed grid voltage testing is essentially a wrong method, and I do not think this has changed recently.

A good word about Quality Testers. Some people think a Quality Tester is for amateurs only. Well, I will use the word amateur later in this text :)

A good word about Quality Testers. Some people think a Quality Tester is for amateurs only. Well, I will use the word amateur later in this text :)

Specially when people understand how tube curves work, if armed with a curve tracer, they become bad listeners. They say, they don't need a stupid old Quality Tester anymore. (I think they never owned a good one, or they would not say that). The opposite is true! and the following text is about this subject.

Myself I had the same opinion at first. I was focussing on fixed grid voltage testing, until I found out, my Funke W19 and Hickok testers sometimes qualified a tube as 'strong', which by my fixed grid voltage method were supposed to be 'weak'. I didn't understand it. I was using my own self-made limits, which I thought I were so well done. After a lot of comparing, my final conclusion was, the Funke W19 and Hickok testers (I have a few) are the ones that do it right, and myself I was doing it wrong. If such fine machines from the past, made by real experts, say something else than I 'thought' myself, then it is pretty arrogant to say these machines are wrong. Well, every day new dreamers will wake up, but myself I don't dream about this anymore. Another approach is the following:

Let me ask you: Do you think a digital tester will give a more accurate Gm reading than a Hickok (quality) tester. You will say, yes of course, the digital device was MADE for this. (I agree with this!).

So here comes another question: What do you think makes a tube fail in equipment in the first place? If a test result says low emission, or low plate current? (at fixed grid voltage). Now if you say low emission and low plate current is the same problem, you make a fundamental mistake. What is right (with this mistake), of course a bad tube will have low emission and low plate current (at fixed grid voltage) at the same time. What is wrong (with this mistake), is that a new tube may show significantly lower than average plate current (at fixed grid voltage), but of course will test very strong for emission. This is very difficult to understand, and you people make it harder for themself, by BEGIN thinking it should be always the same.

The fact, that it is not the same, you can it already see here: You can change Plate current with the grid voltage, but emission you cannot change. Please think of this carefully. (Well you can However, change emission by reducing the heater voltage). Why this is so different, is evident. If a worn out tube fails to work in a circuit, you can never force it to work by changing the bias. That is because emission is low. You can However, force it to work with 25% higher heater voltage. Here you see again, plate current and emission are something totally different. In simple words: Plate current results from emission, and not the other way around. Of course that is clear to everybody, but it should be just as clear then, it is something totally different indeed. So in case you find find out what emission the tube has, the whole shebang with curves or parameters you don't need, result is still more reliable. Provided of course, you use a real Quality Tester, and none of the many fake products that were made for decades.

So a tube with good emission, is good tube by definition, when there are no shorts or leakage. It is as simple as that. Of course that doesn't give you any parameters, but that was not the question when you test for emission.

Sometimes customers with a curve tracer, send back NOS tubes, because they say they are BAD. The strange thing is, the curve tracer didn't say so at all. Because there is no way for that. So when I ask the buyer, what test limits he uses, and from what source he has that information, the answer is: 'ehhhh...well... that was is my own method, but I used it with good result always'

Then I say: No, no, not always, because the first time you talk with me about it, you are already wrong. Because I test them on a Hickok or a Funke W19, and they are GOOD. So indeed, we have the situation, people buy a curve tracer and think they know it better than two generations of Hickok engineers who made those superb testers for 50 years.

When I ask curve tracer users in detail how they do that magic, they simply expect all tubes to be average +/-10..15%, (and here it comes...) tested with fixed grid voltage. But that is not how it works at all. This was never written in any datasheet or test manual. That is a clear case of monkey see, monkey do. You can show me a tube manufacturer's information which declares this a correct way, and I will revise this text. When you search had enough, you will find even RCA and Telefunken saying testing with fixed grid voltage is not allowed to do. Please don't tell me they were all wrong.

So where are we with Quality Testers?

The aim of a Quality Tester, is only to find out if the tube will work or not. This makes sense for instance when a tube TV doesn't work. You just remove all 25 tubes, and plug them quickly in a simply Quality Tester. The one with the broken heater or lost vacuum, you will find quickly that way. By the same principle, it should be clear that you can not detect grid leakage that way, or other nasty failures which may as well make the TV unit fail. So those cheap Quality Testers were often bought by people, only to find out they're pretty useless. That is why so many are optically still new condition, and why also today people don't keep them very long, after finding that out. Some however, are really excellent devices. With the most popular being the TV7, and the best being the Funke W19. Just to give you an example: Funke W19 tests tubes 12AX7 not at 1.2mA because that is the usual point in amplifiers. Funke is not interested in that. They want to know the quality. So they test the tube at 3.2mA, and at far too low working voltage. It is obvious that weak tubes will fail with that, though probably still works at 1.2mA. Funke is still not interested if it "still works" at 1.2mA. If you want to know it's a STRONG tube or not, go for 3.2mA at reduced voltage. Even so, their "?" range means not: "We don't know, find it out yourself". They say if that tube appears to work in the application it is used in, you can leave it in. Just they say, it will not work in very demanding applications. That is clear language, and you won't find that with any other tester. So you can feel happy to own such a tube, and perhaps it may test fine on a digital curve tracer. But when we talk about purchasing a Telefunken ECC803S which costs 400 Euro for a good used one, and 1500 for a NOS, do not purchase it when a curve tracer says it's good, and Funke says it's only "?". As a rule of thumb, you will see that such Funke tested "?" tubes, will often pass at an auto bias test at the lower limit of "good" . Which comes down to the same, so such test results say, it may work now, but not extremely long. This is what an emission test is intended for, and there is no "better" method.

In his 'blue book', Max Funke writes the following. I have edited and translated this for better understanding.

The principle with an emission test is, when a tube obviously has:

- No shorts or leakage

- No gas

- A lot of cathode emission

then it can be assumed that all data is good as well, because what makes a tube change, is these three things. After the above three conditions are met, only control grid functioning needs to be proven only as such, and the tube is expected to meets it's data sheet values.

The above is sometimes declared "too simple" by people who do not own a W19, and never will. But it is not simple at all, to do this right. Because it needs full power testing, so full 250mA if needed. Better ask somebody who owns one. Or judge it by the market conditions for W19 testers. Though many are made, few are for sale, and they quickly go for a high asking price.

So the cheap alternative is below here. You can buy 20 different ones each day on Ebay. Such crap was sold like sliced bread in the 1950's and 1960's. Even today on Ebay these items give buyers the suggestion, little technical skill is needed for tube testing and yet get a reasonable result. Just everybody sells them again after a while, so sales will never stop.

A good Quality Tester is easy to recognize: They are expensive, big and heavy, with many sockets, and often have seen a lot of use.

Some testers can do two things at the same time, like combine a parametric test with a quality test. Like AVO Mk1 and higher are famous for that, but also L3-3 can do that, with specially made cards. Quality testing and parametric testing, in most testers However, is not combined, because it requires too much circuitry, and also because there is no market need. So who wants to know quality, normally wants to know only that.

It seems impossible to put all testers systematically nicely in categories. But I will try to sort them a little bit.

Load Testers

These are a certain kind of the Quality Testers. These can work both with AC or DC anode voltage. With those, the tube under test is used to supply current to a load resistor. The tubes are normally used in diode mode, because the interest is just to find out the emission, and eliminate behavior of the grids. Why is that done? Why not look at what the grids are doing? Well, look at this EL34 tube as an example. It reacts extremely strong to mechanical tolerance on the grid. This can easily make the tube draw 30% more current as average, new out of the box, with a unused, 100% good cathode. So plate current of a new tube can be 100mA +/- 30%. This is not because of weak or strong cathode, but because of grid distance. So a new, fine tube can be from 70...130mA at fixed grid voltage. Let's take two new tubes out of their boxes. One has 70mA, the other has 130mA at fixed grid voltage, but both will have 100mA in auto bias.

On a parametric tester the 130mA tube tests very strong. So to say at 130%. Now, after 5000 hours, life of an EL34 comes to an end. The cathode has only at appr 80% emission, and the plate current of initially 130% has dropped to probably 100mA. Something similar happened to

Now, let's look at the same tubes, but this time on a good quality load tester. As it was new, and tested as diode, this eliminates the function of it's three grids. So now we are finally only looking at the cathode quality. This diode tests at 100% when the tube was new. It should be clear, that this tube after 5000 hours, when emission has gone down. Let's say it dropped 20%. This is indeed the same for both tubes, and a good emission tester will come with that result. This reflects the condition a lot better.

To have the aha! effect, do the following, which is really interesting. Take an weak EL34, which you wanted to dispose of away anyway. Test it on a parametric tester, and it will do only 40mA instead of 100mA. So it is bad. Now, use the tube as a hammer, and knock the sides on something which is hard, but will not break the glass. Like a piece of wood. Re test it with fixed grid voltage, and voila! the current is now 55mA instead of 40mA. Please do this indeed, you will be much surprized! So has the emission improved? Of course not! So how is this to be explained?

In case you own also a load tester, you should also test the tube on this one, before you do the destructive knocking on it. So by the simple logic, that this knocking can of course not improve the emission, there should ne no difference. The test result before and after knocking will be the same indeed. These are only words here, but when you really tried this out, it will open your eyes for this subject. So you can't fool a load tester with this, but you can easily fool a parametric tester this way.

The quality of the load tester itself

DC types are the best, these can more accurate predict the behavior of the 'diode' and give more reliable results. This is so, because diodes by nature have low impedance, meaning they react very strong on voltage changes. So things like random mains voltage variations, or voltage drop of the power supply, due to load, or voltage drop of the whole transformer with tubes of very high heater current, these are things with quite an influence in the test result. Yet, very good AC types exist indeed, with separate heater transformers, like the Neuberger, Metrix, or AVO, but unfortunately it is so easy to build a piece of junk too. They can be build almost without electronics at all. So in a minimum version, inside you'll see only wires, a miniature transformer and one resistor only. And of course very few sockets. Such are cheapest to make and easiest to use. . Most radio and TV repair men had them. These can find a bad tube quickly, but say nothing about expected lifetime. Like a bad dentist, and soon after his work, you have new trouble. Such tube testers do pick out bad tubes often, but let some of the dirty ones pass. If your requirements do not go any further, this kind of tester for you. Actually some of those CAN be really good, but these are very few only, and most of them are toys. Specially the often seen Lafayette, and clones called like 'TC-02' etc, are useless.

New made testers

I am a bit reluctant here. People are often impressed by the illusion of digital precision. But really there is limited meaning in a number like 60.05mA and the tube is tested with cold anode, and current is down 10% because of that. So you read 60.05mA with 10% error on it. Or like AT1000 is doing, presenting the transconductance of a 6SN7 with four digits, but stepping like this: 2500, 2600, 2700. Adding fake zeroes to a number, is presenting fake resolution, so a 2550 tube may as well read 2500 or 2600. Any 60 years old AVO will do better.

I am not against digital testers, but I am against fooling the user with fake precision. Which unfortunately is more often done, as not done. So the choice comes down to what is your 'must' for you.

The mostly asked question is: How good is a used tube, and what's the lifetime left in it? It is so weird, but all new made tubes testers avoid this answer, but give you all kind of data to impress you, but do not tell you what you need to know. Moreover, and I need to say this very clearly, parametric results are not ideal to find out remaining tube life. So they tell you about parameters, and no more. Lifetime is rather domain of the Quality Testers, which are made for this purpose specially, and they give you not parameters, or best way a somewhat useful Gm number as many Hickoks do.

Vintage testers seldom present parametric information to the operator. Yet in the end they come up with the answer to your question. They present on a good/bad scale the condition of the tube. After some experience with that tester, you will understand what '85%' means to you, for this particular tester and this particular tube. A few rare Quality Testers will can also present parametric information, along with the quality percentage.

Good Quality Testers are: Most of the Hickoks, AVO Mk2, Mk3, Mk4. Funke W18, W19. (very incomplete list! ). The useless ones, are no real help to you. So the 150...300 Euro these go for, is a waste of money.

Value: When this is an issue to you, a vintage tester always keeps it's value, and new made products not so much. With vintage tester's prices, the most expensive ones are the easiest to sell, because everybody wants them. It's like with vintage cars. There are many rusty cars for sale everywhere. But when you want a specific model in rust free fine condition, that will have a price tag. Yet, this car will hold it's value, and stays easier to sell than a piece of junk. With vintage tube testers, it is just the same.

Why use a vintage tube tester?

This repeats some of the above issue, in more detail. Vintage testers offer functions, which new made digital testers do not have. Digital testers suggest precision. However, that is very probably not the case, and not what the average user needs. Most people in reality only need to know: Is the tube still good, and how long will it still last? Modern testers like the AT1000 give no answer to that at all. Even so the AT1000 is a very confusing tester, and it makes many mistakes. So fine, you know the plate current is for instance 81.5%, but 81.5 of what? Wel.... of 100% of course. But was that the question you had? Will you reject this tube, because 81.5 is not 100? You and the digital tube tester make a bad team, if neither of you don't know when a tube is bad or not, and at least the AT1000 does not know it. Put the same tube on a Funke W19, and it says."20. Good starts at 12"' Look! Now that is clear. Put the same tube on a Hickok and it will come very far into green. Wow.... and you were so disappointed about only '81.5% of 100%' as the AT1000 told you. Such experiences I made many. Or even the AT1000 will say the tube is at 100%, so you are happy. You put in an amplifier and after 10 hours the speakers say: 'CRAX&%&%$'. Well, you better should have passed it through the Hickok or AVO leakage test, that would have spotted that leaky electrode, which the AT1000 cannot test for this. Or, you dig up some radio tubes from the 1940's and the new made tester -OF COURSE- doesn't have the sockets for it. Or the settings are missing, which you can -OF COURSE- make yourself, but is that what you wanted?

This is what I always say: You must see of a vintage tester as a concentrated amount of knowledge and experience, put into that machine, by those old tube specialists, and you're now buying this experience and comfort, along with the old tester. The lack of experience with makers of new tube testers, such as AT1000 is painful. So if Hickok found out exactly this or that setting to reject a 6SN7, you can never replace that by a simply plate current measurement. I have learned to trust a test result from a vintage tester which is a good condition, more than what digital testers tell me. I have a fully restored Hickok 750. Though the size a large, I love it. When this tester says: 'Bad tube', well than that's what it is. At the moment I see many people returning to those good old analog tube testers, and I can understand it.

Another compare is with the uTrace or E-tracer curve tracer. Same situation here. In contrary to the AT1000, the software of uTrace and E-tracer is constructed with a lot of pride, and regularly updated. These little testers can do so much. However, also here, you have to judge for yourself if you like the test results or not. The question is, are you really capable of that. There is no help for the user, saying if the tube is good or not. So I see often people inventing self-made rules, for when a tube must be replaced. Such rules are mostly wrong. Of course they have no other option, but that doesn't make the situation any better. That is because the digital testers don't help hem saying if the tubes must be replaced or not. To my opinion, such people are better off using a really fine, vintage tube tester.

So I prefer to test a tube with a professional tester, from the period when these tubes were in daily use. These were made just to say how good the tubes still are, and for me that is often the main question. If the tube is still 'fine' by such a tube tester, then transconductance etc suits normal applications. For very old tubes like the 45, or old rectifiers, I prefer an old (but good) tester like for instance the Hickok I-177. It gives me both 'Gm', and 'Quality'. Whereas the later model TV7, gives only 'Quality'. Very high gain tubes like ECC83 should not be tested on an I-177. Though official settings were created later, the input signal to this tube is too high. Such high gain tubes didn't exist at the I-177 was designed. Or, the AVO Mk1...Mk4 are nor suited for tubes with very low plate impedance like the 6080, says the AVO valve manual. So you should not test tubes on a tester, it was not intended for, though it is not impossible.

2) Perhaps this is the best place to advertise our calibration tube set.

Order Numbers:

624-014-55 Full Package Contains the four items below. (These can also be ordered separate)

|

|

The use of calibration tubes.You can say at every AC Tester, you simply need such a tube for calibration. There is no other way as to take a known tube, and set the tester's reading for that value. From the Hickok company, you could even buy them, but that is long ago. Even so if you would find one of the flee market, it will not have it's value anymore after 50 years. At AVO they recommend smaller tubes, such as ECC82 or 6SN7. Also for any DC tester they are a safe ways to verify the tester with a range of tubes, and check at several operating points. Also important is to check the leakage function of your tube tester, you need the leakage test tool for this. First the tester must be able to detect leakage in a reliable and predictable way. Then, if this function is verified, it also proves the deck with the sockets is not leaky. Very infamous for this are 40 years old coffee drops inside the sockets, or the work a fool who sprayed everything with contact oil. (and then sell the tester, frustrated). Where are you now?Most tube collectors have a tube tester, that was not serviced for 50 or 75 years. Those testers that have serviceable parts inside, are likely to be off calibration in a terrible way, it shouldn't come as a surprise. If the tester was stored in a basement or a garage for the last 30 years, the components usually suffer from this very much. Capacitors have gone leaky and carbon resistors will have higher resistance from this. This condition is where most tube tester are in, specially the Ebay ones. However, most things inside the tester can be repaired professionally as long as the basic material is good. With this I mean the panel meter and the wiring too. With an unknown condition tester comes first VERIFICATION, which means you check tubes with known values, and the tester should reproduce this within it's specified tolerance. Then, normally you find larger deviation than that, and you can do a calibration attempt. This means you calibrate the tester with a known tube. After this, some other types of known tubes should also indicate correctly, which is not necessarily the case. If you calibrate the tester for a 6L6, next you need to try if it works well with a known 6SN7 to see if it does the small tubes nicely. A known 6SL7 is good to find out it the tester works well in the 1mA range for plate current, and 1Volt range for grid voltage. Suppose you find out then, your tester has some deviation even after calibration, you can still decide if you want to keep it, or repair it. A repair is probably due, when you can calibrate the tester for 6L6, but 6SN7 is indicated wrong. Then calibrate it for 6SN7, and 6L6 is indicated wrong. ---> Also you should click here if you want to calibrate your tube tester <--- Customer feedback from Sweden, for the calibrated tube set

Use this burn in device! So ok, we want to test those tubes. Still keep in mind, test results of unused tubes can change very much within the first 2...7 days. Moreover, the burning in effect of used tubes gets lost after storage. Depending on many factors that can begin already after 3 months. Any used tubes that were stored for years or decades, you may as well regard them not burned in. Before worrying about how far off transconductance or plate current is, a good burn in may change your mind about the tube(s). When you noticed for the first time how a supposedly 'low emission' or 'leaky' NOS tube recovered completely after a longer burn in, it will change your view on this. Some tube testers can do that, but it's questionable if you want to run your tube tester for a whole week, PER TUBE. You also wear out the tube tester. So burning in a quad for 2...7 days per tube would take you even a week when you want to go for 7 days per tube. It's not possible realistically. Besides most tube testers are definitely not made for continuous use, and damage itself or even the tubes if you do. Here is a link to a DIY burn in device by Emissionlabs.

* * Scroll down to read about tube testers! * * |

|

3) FOR SALE ITEMS

Prices here are for export outside the EU, no VAT. Please ask for a quote including VAT if you want to buy the items in Europe.

I am planning to retire, close my business, and sell off the tube tester collection. Some are already sold, but some nice items are still available.But really, NO SHIPMENT OF TUBE TESTERS. I am very sorry, and I hope you understand it. They are too difficult to pack, and it's just too annoying to see the nice items being damaged by the carrier companies, and then we both get stuck in insurance issues. So if you are interested, you can see the tube tester working before you buy it. You can see what a good old tube tester can do, when it has no defects, and is well serviced. Please contact me, perhaps I have something for you. But it has to be picked up here, in South Germany. Sorry, for making no exception. So this is useful when you live near by, pass by here on a trip. You can bring your favorite tubes, to see how they test. We are near the city of Stuttgart here, 90 minutes driving from the Swiss or French border. Ready to sell:AVO Mk4 in near mint condition. With tube data book 1968. No rusty screws, no sun burn on the knobs or the meter. Everything is nice and clean. All switches lubricated, pot meters cleaned. etc. Calibrated and amazingly accurate. Panel meter has no linearity error, no stick-slip effect, and exactly 30uA full scale as it should have. I t was always my favorite in the lab, but times come to an end, and I am selling all equipment. Price 3500 Euro. Hickok 750. In very nice condition.750 is a highly upgraded model of the 534 Series, with more parts inside, it is more accurate, and has more options. Hickok 539A.Unserviced. It works and tests tubes, but results are too low. The inside looks complete and not worked on. I just never found time to start working on this one. The |

4) How to test tubes, on various testers

Haven't we all read this before on Ebay:These tubes all test "GOOD" on my TC2 Tester. Each category of tubes is tested different.

The problem comes, when you want to know the quality of a used tube. There was never a general method published for this by any tube manufacturer. In the 'Blue book', which belongs to the Funke testers, is a piece of text about this, and it is the only reliable information about this that I know. This was always left up to manufacturers of tube testers. So... it means: Many tube testers, many methods. Some ways to test a tube1) Plug in a brand new tube in your amplifier, and see if the function improves. This result can't be denied! The method was used by many service technicians. The tube manufacturers had special cases for that for service man, with a collection of new tubes, one of each. If you have no other way, take this way! It is a very good one. 2) Measuring the DC plate current in an AUTO BIAS circuit is a good thing because it is realistic, and it's hard for the tube. This is no job for a low cost, or also not for a 'patented' tester. There is nothing to patent on a normal, straight forward DC tester, and this is the ONLY 100% safe way for power tubes. So once the tester has patents in it ... Well may be they are good, but I would not trust an unknown brand.

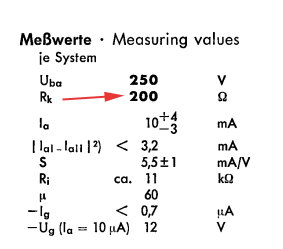

It is supposed to give 10mA at 250Volt plate, and Rk = 200 Ohms. It is 'good' when not higher than 14mA and not lower than 7mA. This is from the original Telefunken datasheet (can be found at the tech-corner of this web site). The end-of-life is below 6mA, or when the original value it had when it was new, has lost 40%. It should be obvious you cannot repeat this data without Bias resistor! Well you can but variation for a good tube will be significantly larger than +40% / -30%. How much larger, nobody can say, and it is not interesting, because fixed grid voltage testing is a wrong method to determine quality, anyway. The RCA datasheet of 6922 is clear about that. Though characterized at 15mA, guarantee ends above 5mA with fixed grid voltage. Now this TELEFUNKEN datasheet is a very clear specification :) So of course THIS is what you like to verify. The GE datasheet of the KT66 simply says below what current the tube is bad. Unfortunately these are the good exceptions, and most tube manufacturers avoided that question like monkey plague. When measuring real DC plate current, you need very precise and heavy electronics, these tube testers are expensive, and may need calibration or periodically verification of the tester. In the instruments world the definition about calibration and verification is a reversed one. Please take good note of this. It means when specified NOTHING, the instruments needs yearly calibration. If it says it needs a calibration every five years, then this counts instead. So no information = Yearly calibration. This the way the world of instruments is defined. So if your tube tester is from 1965, nothing is written about calibration in the manual, and it was never checked ever since, FORGET the results. It missed the calibration every year ever since 1966. Verification is a process which must be specifically ALLOWED by the instruction manual. So when not mentioned, it is no good way to test this tester. Verification means you compare the result to a know tube, and when ok, the tester is ok. VERY FEW tube testers are so good they can be checked that way. For instance Funke W19 can be checked that way. When is a tube good or bad?

In lack of manufacturers test data, take not 60% from the datasheet 100% value at fixed grid voltage, because that should not be used for anything in a serious way. Take 60% of the initial value the tube had when it was new. That initial value may have been lower than the 100% value or higher. Hard to say what the initial value was after many years. The best is always to mark it on the tube. Otherwise you have a dirty method here. To give an example: a tube has for instance a 100% Value of 100mA, by the datasheet Suppose the initial value of YOUR tube was 70mA, when it was new. A European tube may drop down to 70% of that, so 49mA and is still good. But.... suppose the initial value was 140mA, then 70% of that is 98mA. Below that the tube is worn out! So you see how important the initial value is. Always mark it on a new tube when you know the value. Has the initial value got lost, you have to guess it. 3) Measure Transconductance. This is also good, because you can construct good tube testers, with little electronics, and get useful results from that. These often need no or little calibration, or just verification. So verification requires a calibrated tube, or another tester of the same kind to compare the results. However.... Testers that measure transconductance with little electronics are not never accurate with ALL tubes, and that's per definition. So the Hickoks are typically calibrated with a 6L6, and you can fully trust the readings with any kind of similar tube, like KT66 or KT88. However, they are not capable of testing tubes like 2A3 or 300B under real life conditions. These are 5000 micromho tubes, but on the Hickoks they read only 3000 micromho. So these test results cannot be used to verify against the datasheet, but the severe deviation is However, integrated in the roll chart, and like this it works well. So the roll charts just take another bias voltage which will make a good tube indicates good, and a bad tube indicates bad on the red-green scale. How about precision with that? VERY good, I would say, you can trust a good Hickok always.

Some very good testers however, are the higher class Hickok testers. These perform a real transconductance measurement, with a (known) Grid bias voltage, put a known AC signal on the grid, and from that measure the real AC plate current. Keep in mind, ALL Hickoks work with AC wave shapes, that represent equivalent DC voltages, and this limits the precision, no matter what you try or do. A better method for this, is not using the mains voltage a signal, but a higher frequency from an oscillator. Why is that? You may say you can also measure transconductance at 50 or 60Hz also? The answer is: No you cannot measure that precisely at the mains frequency. Reason is, if the tube is humming (so it has a defect) the hum signal will be a part of the plate signal. So such the tube will read better than it is. The Russian L3-3 uses a 1400 Hz sine wave at the input of the tube, and a 1400 Hz selective Voltmeter. This is in fact a very band pass filter. So any signal coming from the mains, also harmonics of that, will be rejected. Also distortion and white noise of the tube is not added to the result, since only 1400 Hz is measured, within a few Hz only. The second harmonics is 2800 Hz, and filtered out. This method is the one and only true measurement of transconductance.

SHORT OVERVIEW OF TUBE TESTER FEATURES IN EXEL FORMAT: -> CLICK HERE |

5) About accuracy and errorsMaster Confucius (500BC) was not confused at all. He said there are three ways to learn from errors.

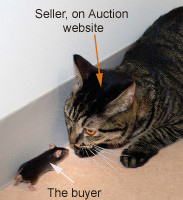

When somebody offers such a tester as you see here on the left, all the seller needs to do, is picture it with a shiny new EL34 Telefunken, the needle nicely in the green, and everybody thinks: Wow! That is what I need! The price is 100 Euro higher as when pictured without a tube on it, because obviously the tester does what it is supposed to do. This is also the way a weather rock works. Suppose you put a broken tube on this tester, it will not move the needle, or only half way. So if If this is your level, you will like this tester very much. Their practical use was for quick TV testing, with 25 tubes inside. Radios and TVs were made such that they work still when a tube is weak. This is the merit of good circuit design. Such a (good) circuit only stops working short before a tube breaks down completely. So the service man doesn't need to know much about the tube. The only thing he needs to know, if the tube has broken down. So he just pulls out all 25 tubes, and he is not interested in all kind of quality bla bla. He wants to know which tube is bad. I have repaired many tube TVs myself, and indeed, the bad tube is always only one. Simply, because that's the moment when they called the service man. So quickly check of the needle moves, and 15 minutes later the broken tube was found. Test the TV with a new tube, and hurray, it works again. Some pick out a few more tubes, and have the poor owner look at the needle, which stays in the red. There is quickly agreement on a few more replacements, to do extra business. That's what this tester was used for. And no again, such testers tell absolutely nothing about tube quality. No no, also not just a little bit. That would be a mistake to think so. There is almost nothing inside, just three resistors and a too small transformer. Really if that was the big idea for how to test tubes, they must have been pretty stupid at Hickok and AVO. These weather rock testers are fake. But it is great fun to see people outbidding each other like nuts on Ebay:) Value: You can pick them up on flea markets for any price around 50 Euro. Picture then with a broken tube on it, and the needle in the red, and you get 200 Euro on Ebay. Or picture them with a NOS Telefunken tube and the needle in the green, and you get even 250 Euro. The best is with an NOS KT88, if you have one, you may get even more than 300 Euro for the tester.

During the night, there is further use. You have to inspect the rock, and when it has gone white, there may be snow all over the place when daylight comes. Or, if the rock becomes invisible during the night, that is means there is no moonlight, and you should avoid hunting. But if the rock becomes invisible during the day, this indicates thiefs are around. So you see, in many ways this rock helps to increase the safety of the camp. I always like to think, those cute little tube testers below, where invented by the same person who invented the weather rock.

You should also try the link there to my fellow countryman and MIT professor Lewis. He has a nice youtube video about accuracy of measurements. Part of his lecture was even on TV. This video of him is not about accuracy, but also nice

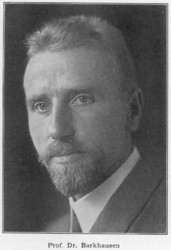

Since Gm is essentially the wrong way to express this, we have to learn to say S in mA/V. I never understood the practical use of Gm in mMho. Do you? I don't. Trying to understand what a Mho is, really hurts my brain, but mA/V I can understand that right away. So forget mMho and use S. Then we get: S * Ri = Gain. Then there is this 'D' which is 1/gain. Actually that was only used to make things more complicated, and nobody uses it 'D' today anymore. But Barkhausen added that twice in the same formula. Same is A * 1/A is 1. He added some artificial magic to it, and then he came up with:

D= 1/Gain Originally, this behavior of electron tubes was observed first in 1914 by a man named Hendrik J. 'van der Bijl, at Western Electric research labs. As they saw no practical use in that, Western Electric did not follow up on it. Well we all make mistakes sometimes :) |

7) Some buying AdviceHave you already been cheated with a tube tester on Ebay? Welcome to the club!

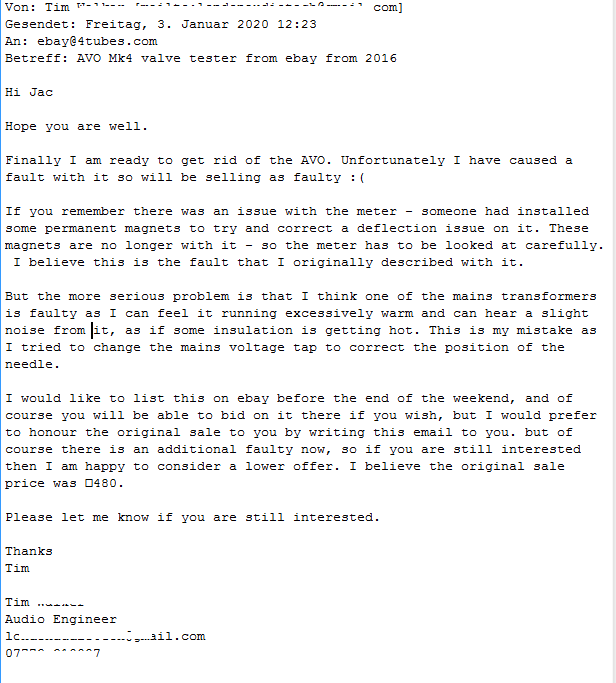

An EBAY Experience from 2016 to 2020. In 2016 I bought on Ebay from a person in London, named Tim an AVO Mk4. He introduced himself as an "Audio Engineer" but when I checked his address on Google, it was seemed a small guitar shop. Anyway, he offered the tester as faulty, for 480 Euro. So I just bought it, the meter alone is worth it. And then the Ebay mess begins. He did not want to ship it, the poor guy had no shipment materials. So I have to pick it up, take it or leave it, he said. Well I said I take it, but I can send you an appropriate box, with double inside box, and plastic chips in it, and a roll of duct tape, so you have all you need. Well that solved his problem he said. Sending that cost me 15 Euro and the boxes I have to buy too. He just could not tell the shipment cost yet, only after packing. So I said, no problem Tim, let me know the total then, when you are ready. Lots of bla bla went back and forth, but never any answer about how much the total was. So I wrote the 15 Euro off, and that's it. Much to my suprize, he offered it two years later to me, some circumstance had came in between. But now he was ready to finalise the sales. So I said, well Tim, let me know the total, so 480 Euro + shipment. No answer came. Then, another two years later, in 2020, he contacts me again. In the mean time he totally messed the tester up. Somebody took the magnet out of the meter, and it got lost. Probably this somebody was called Tim. Oh, and the transformer is now burned as well. (by somebody called Tim?) But anyway, he is now ready to sell it to me. This not a deal with a Nigeria connection, but a guitar shop in London. But this time in 2020 he seemed afraid 480 Euro was not enough. Mind you he sold in on Ebay to me already in 2016 for that price. Meaning it is my property already. But never told me the total incl. shipment. He said he caused an additional fault with the tester, so NOW he is willing to sell it. He will list it on Ebay again, and when I am interested I can bid on it. The expertise of this Audio Engineer is remarkable. After four years he found out there is no magnet in the meter. And that he was able to diagnose as the reason why it was not working. I don't want to know why the magnet fell out, but i never had such a case yet myself. This is just a nice example of what things are sometimes normal on Ebay. Moreover he burned the transformer, as he writes, by running the tester at too high mains voltage. Here is a screen shot of what a London Audio "Engineer" wrote me. I scrambled his name, but he does not deserve it. This email is REAL.

Here are some observations I madeWhen the tester is sold as 'defective' they bring half the price of a perfect one. So defective testers is nice business. When they are advertised as 'from my uncle who passed away', buyers regarded that as ideal, because there is common belief that uncles give the good items to their nephews, and dispose of the bad ones before they die. Forget testers that were found in a garageYou can't fix the rust with contact spray, or remove the fungus with a brush. Or, the seller says it was 'found on the attic' and you think that is good, because attics are dry. Well, you will may find out the reason why somebody put this tester asleep 40 years ago. For instance the transformer has a defect. Then today, first you have to repair the rusty switches and bad contacts, and after that you will come to the same conclusion as somebody 40 ears ago, because a transformer does not self repair by storage. Such a thing happened to me before. I Was ill for some time, after suffering a severe electro shock from 830Volts DC. During that week, I restored an old Telefunken radio from 1930 or so, which I kept for some rainy days. Don't laugh, but I bought it 15 years before that, from a farmer, who had all kind of junk in a sheep stable. It was almost for free, so I thought ok, why not. Well I found out, why not. I know it was a mission impossible. After removing the sheep hair, mouse drops and little dried up bones from within the RF coils, etc., I got the circuit working, step by step. Then came one problem, I had to re-wind the speaker field coil. (so not the voice coil). I repaired that, and I got the whole radio playing almost again, apart from the oscillator-mixer tube which has such low emission it did not oscillate any more. It was a 4V tube, and I put it's heater on 6V and then the oscillator worked. Below 6V, the oscillator went off. The tube was bad, and it was a very expensive one. It cost me 100 Euro, but at least it was NOS. So long ago, somebody put this radio aside because it was not worth it to replace the speaker and a tube, and apparently it was not worth it to put back cover in place, and also he cut off the mains plug. So long ago, somebody said: Forget it. And he was probably right, because by then, tube replacement was often a death verdict. Well I try to remember that lesson. So.... Don't buy a tester with a cut off mains cordThis is really a no no. I see only two options, and how to keep those apart. 1) the sellers cuts if off, as an excuse for not having to say the fuse blows out all of the time, or the transformer is smelling, or things like that. 2) Long ago, the mains cord was worth more than the tester. Does the cut show bright clean copper? So it was cut off by the seller. Was the cut off old looking old? Then 50 years ago somebody needed a mains cable and cut if off this tester, before getting rid of it. 110V tester from 230V region. "untested"When you buy a 110V item, with the USA connector still on it, while living in a 230V region, the seller claims he has no way to test it. If he really found it somewhere, would you he not buy an auto transformer on Ebay for 10$?? Probably yes. And then what will he do if the tester appears totally broken? Look at the deck screws.Don't take a tester with the deck plate screws missing, or it has shiny new screws. It only means, long ago someone thought it wasn't worth putting it back together, and the screws got lost. Damaged case, or just a very much used case.This is a very reliable hint: If case looks treated like junk, do not think the owner had a different attitude towards to the case and the tester itself. More likely the owner treated the whole tester like junk. The question is only, what makes you think he was wrong? Or, a tester looks extremely used, but nor abused. Specially around the leakage switch, it is very much used. Though this doesn't look nice, but it may be a very good sign. Obviously it was used if for decades by somebody, and he had reason to keep on using, and using it. Take only a tester that is guaranteed to be OKIdeally it was used by the seller itself. It won't be cheap, and still the seller knows better than you why he sells it, but you get at least a basically working tester. Sorry for the lecturing, but i know this from the many requests from people who bought their broken testers on Ebay. SO WHERE DO I GET MY TUBE TESTERS FROM?Most of them from people I know. Though sometimes I have no other choice than Ebay. In that case, I only buy when I can send the item back, or when the item is such low cost that I can sell it as defective and make no loss on it. This is a good example. I received an AVT CT163 from a collector without pre payment, and option to return if not as promised. Actually he told me later, he was afraid to ship it to an unknown buyer, and get trouble afterwards with buyers claiming fake trouble, sending the item back, abusing Ebay or Paypal. In his country, receiving such a delicate item, packed by somebody who gets his money back anyway, was no option for him, and he might even have to pay tax on it. So a permanent sale is what he wanted. Needless to say, this worked out good for both parties. We stayed email friends afterwards, and he bought a pair of vintage fog lamps from me, for his Mercedes car collection. In case the seller reads this: Thanks you JS, for this wonderful VCM163 from South Africa. The following link is a bad example. It shows information about a very clever seller from Hungary, who fooled me badly. I heard later, I was not the only one. He is still on Ebay, playing innocent. He claims to be "private", but he means to say with this, he has not registered his company. He has a massive trade volume, selling under changing names. His adverts still look the same, and shipment city is Budapest. Beware for any tube tester from Budapest, and the seller has tons of other items. LINK to Ebay PROBLEMS. Here we go again. Some popular vintage testers.

|

||||||||||||||||||

Brand |

Model |

AVO3 |

Mk2, Mk3, Mk4, VCM163 |

Hickok |

TV7, I-177, 750, 539C |

Neuberger |

RPG370, RPG375 |

Funke |

W19, W20 |

Kalibr |

L3-3 |

ELPO |

507 |

METRIX |

U61 |

Click here for analog Testers Part1. (Better use the menu at this page top)

Also it is much later build. So internals are newer, and it can test the latest generation very high gain and very high micromho (frame grid) tubes. Which earlier Hickoks can not do as good, or not at all. Yet it has also all sockets for the older tubes still, as well as sockets for wired tubes. ("Pencil" tubes). All together making it such a perfect tester. Revised roll chart, using original gear wheels. 230V transformer build inside. Repair report is on this website. All internals serviced, and calibrated. Very good working, calibrated, clean panel meter. Hickok 750 has in addition to the normal Hickock method, also a variable DC power supply, with current monitoring, to test whatever device you want. Such as testing the voltage-Current curve of rectifiers. It is one of the very few Hickoks which can test also voltage stabilizer tubes. It can even simulate Funke W19 tests. This is "the" tester, if you find 539 too complicated, but 534 too simple. Such a wonderful tester to use. It has that smell of good old equipment when you open the lid. Price 1100 Euro.

Also it is much later build. So internals are newer, and it can test the latest generation very high gain and very high micromho (frame grid) tubes. Which earlier Hickoks can not do as good, or not at all. Yet it has also all sockets for the older tubes still, as well as sockets for wired tubes. ("Pencil" tubes). All together making it such a perfect tester. Revised roll chart, using original gear wheels. 230V transformer build inside. Repair report is on this website. All internals serviced, and calibrated. Very good working, calibrated, clean panel meter. Hickok 750 has in addition to the normal Hickock method, also a variable DC power supply, with current monitoring, to test whatever device you want. Such as testing the voltage-Current curve of rectifiers. It is one of the very few Hickoks which can test also voltage stabilizer tubes. It can even simulate Funke W19 tests. This is "the" tester, if you find 539 too complicated, but 534 too simple. Such a wonderful tester to use. It has that smell of good old equipment when you open the lid. Price 1100 Euro.  For instance the ECC801S / 6201, from the TELEFUNKEN datasheet:

For instance the ECC801S / 6201, from the TELEFUNKEN datasheet:  DC current testing. Generally it can be said a tube is bad when the original plate current is below 70% of the initial value for European tubes, and below 60% for USA tubes. However, we should only use such numbers if there is no specific instruction in the datasheet. If there is a test circuit in the datasheet (this is so with many long life tubes, or other High Quality tubes) this if course replaces any other test method.

DC current testing. Generally it can be said a tube is bad when the original plate current is below 70% of the initial value for European tubes, and below 60% for USA tubes. However, we should only use such numbers if there is no specific instruction in the datasheet. If there is a test circuit in the datasheet (this is so with many long life tubes, or other High Quality tubes) this if course replaces any other test method.  What is not so good, with 'Transconductance only' testers, is the unknown DC conditions for the tube under test. I have many Hickoks, and I find that a 'bad" tube on by those testers is definitely bad. These tester makes no mistakes with that. But how it came to that conclusion is unknown.

If you do not want to know why a tube is bad, but you are only interested if it needs a replacement, a Hickok is THE tester.

The ideal way to measure transconductance is with an AC (audio) Test signal, and adjustable DC and original datasheet settings to go with it. Very very few testers work like this.

Almost every tester has it's own way to avoid this. Reason is, as said before, expensive electronics.

What is not so good, with 'Transconductance only' testers, is the unknown DC conditions for the tube under test. I have many Hickoks, and I find that a 'bad" tube on by those testers is definitely bad. These tester makes no mistakes with that. But how it came to that conclusion is unknown.

If you do not want to know why a tube is bad, but you are only interested if it needs a replacement, a Hickok is THE tester.

The ideal way to measure transconductance is with an AC (audio) Test signal, and adjustable DC and original datasheet settings to go with it. Very very few testers work like this.

Almost every tester has it's own way to avoid this. Reason is, as said before, expensive electronics.  I found almost no tester that can accurately measure the transconductance of law impedance power tubes like 2A3 or 300B. The testers I have, so far the only one that produces an EXACT and fully correct reading is the Russian L3-3. All other analog testers produce values that are quite imprecise. Also the great and highly valued AVO Mk4 doesn't come near. Wisely they left out the 300B of the AVO manual. Also most Hickok roll chart avoid mentioning the 300B. I found out the reason for that, is the too low plate resistance of those tubes. There is a hint about that in the AVO manual, but this hint is written in such a way that you will not understand the real meaning of it. What they mean at AVO is: Forget the results for all tubes with low Rp. The Hickoks also can't measure such tubes accurately if you ask me. Those Hickok testers that can't do it, also don't have the 300B in the manual. If you do test it, by simply put it in 2A3 and set the filament to 5V, you get wrong results. So it will read 3000 micro mho for a tube that has 5500. Also for your 2A3. But... who knows the real Gm of a 2A3 before testing it ...? So nobody finds out, and nobody will complain. The digital tube testers AT1000 ( we have three) is good, but the L3-3 is better. Just not as convenient, and the AT1000 software is a bit crude. The Sofia software is extremely delicate, like you can point with the mouse at any position of the a curve, and you get the three main parameters in one window, for that particular point. (Gm, Rp and gain). Well for me, the Sofia and the L3-3 beat any tube tester I have worked with.

I found almost no tester that can accurately measure the transconductance of law impedance power tubes like 2A3 or 300B. The testers I have, so far the only one that produces an EXACT and fully correct reading is the Russian L3-3. All other analog testers produce values that are quite imprecise. Also the great and highly valued AVO Mk4 doesn't come near. Wisely they left out the 300B of the AVO manual. Also most Hickok roll chart avoid mentioning the 300B. I found out the reason for that, is the too low plate resistance of those tubes. There is a hint about that in the AVO manual, but this hint is written in such a way that you will not understand the real meaning of it. What they mean at AVO is: Forget the results for all tubes with low Rp. The Hickoks also can't measure such tubes accurately if you ask me. Those Hickok testers that can't do it, also don't have the 300B in the manual. If you do test it, by simply put it in 2A3 and set the filament to 5V, you get wrong results. So it will read 3000 micro mho for a tube that has 5500. Also for your 2A3. But... who knows the real Gm of a 2A3 before testing it ...? So nobody finds out, and nobody will complain. The digital tube testers AT1000 ( we have three) is good, but the L3-3 is better. Just not as convenient, and the AT1000 software is a bit crude. The Sofia software is extremely delicate, like you can point with the mouse at any position of the a curve, and you get the three main parameters in one window, for that particular point. (Gm, Rp and gain). Well for me, the Sofia and the L3-3 beat any tube tester I have worked with.

About weather-rock tube testers:

About weather-rock tube testers:  This is a so called weather rock, used by all boy scouts around the world, before building a camp. It works really great and costs nothing. Initially it is used to build the camp with the right angle to the sun. The is done by looking at shadow line at the bottom, which will tell you exactly from which direction the sun is shining. You could also just look at the sun, but you do not have the accuracy a well made weather rock will give you. Then, after the camp is build, there is further use for it. A wood fire is used to cook, but fire can also be dangerous. The fire must be made closer to the weather rock as the camp is located. Then, if the rope begins to smoke, the camp fire may became too large, and you need to make it smaller. Even so, when the rope breaks, this indicates the fire was really too large, and you need to warn the camp guard.

This is a so called weather rock, used by all boy scouts around the world, before building a camp. It works really great and costs nothing. Initially it is used to build the camp with the right angle to the sun. The is done by looking at shadow line at the bottom, which will tell you exactly from which direction the sun is shining. You could also just look at the sun, but you do not have the accuracy a well made weather rock will give you. Then, after the camp is build, there is further use for it. A wood fire is used to cook, but fire can also be dangerous. The fire must be made closer to the weather rock as the camp is located. Then, if the rope begins to smoke, the camp fire may became too large, and you need to make it smaller. Even so, when the rope breaks, this indicates the fire was really too large, and you need to warn the camp guard.

The young man on the right, is Professor Doctor Barkhausen, who set up Barkausen's law. Actually this is not a big deal, but same as Ohm's law is not difficult, the achievement is somebody putting it on paper and he was the first. It's just that Gm * Ri equals the gain/1000. (ehmm....of course you knew that already).

The young man on the right, is Professor Doctor Barkhausen, who set up Barkausen's law. Actually this is not a big deal, but same as Ohm's law is not difficult, the achievement is somebody putting it on paper and he was the first. It's just that Gm * Ri equals the gain/1000. (ehmm....of course you knew that already).

Ebay is not a good place to buy a tube tester. When prices are rocketing, there is too much interest to buy whatever is for sale. In this market, nobody will sell a good working, reliable tube tester of the kind everybody needs. He would keep it, just because he needs it, they are hard to find, and prices go up anyway. That is why they are so hard to find in good condition. What is for sales is the whole category of testers that are of little practical use, or seem impossible to calibrate, or have repairs coming up, have fungus inside, or other reasons, to dump them on Ebay. So don't believe you're going to be the lucky guy, paying only a low price for a fine tester. Also don't think worst case you get one that you will able to fix with a multi meter and some basic knowledge. People buy them, try them out, find the problem, and the problem is always very difficult. I have lost of negative experience on Ebay. You will hardly ever find a tester that you can repair elegantly. I thought so myself too, but that was a long time ago. Typical problems are always hard. Like partially shorted transformers, bad panel meters, none repairable switches for Funke and Neuberger. All kind of things that were impossible fix by the previous owner makes the thing land on Ebay. The seller always tries to appear the untechnical Mr. nice guy, so he wants to put you in the 'lucky' position. Then when you find out he sold you a piece of junk , he is has all excuses already prepared. The Ebay text was formulated with great care, and in the you end up as the 'unlucky' guy. Reality is often, the seller has been trying like mad to get it fixed, and gave up on it. Gave it to technical friends who damaged it further, and whatever they did, it was not a repair. With the crazy prices on Ebay, he just sells it, and buys another one for the same money. WIth a few tries he can be lucky. So he can't go wrong. And nooo... I am not paranoia. You have to read those Ebay adds with a sharp eye for detail. Just look at the above picture. What animals do you see there? A cat and a mouse? It's a cat and a hamster.

Ebay is not a good place to buy a tube tester. When prices are rocketing, there is too much interest to buy whatever is for sale. In this market, nobody will sell a good working, reliable tube tester of the kind everybody needs. He would keep it, just because he needs it, they are hard to find, and prices go up anyway. That is why they are so hard to find in good condition. What is for sales is the whole category of testers that are of little practical use, or seem impossible to calibrate, or have repairs coming up, have fungus inside, or other reasons, to dump them on Ebay. So don't believe you're going to be the lucky guy, paying only a low price for a fine tester. Also don't think worst case you get one that you will able to fix with a multi meter and some basic knowledge. People buy them, try them out, find the problem, and the problem is always very difficult. I have lost of negative experience on Ebay. You will hardly ever find a tester that you can repair elegantly. I thought so myself too, but that was a long time ago. Typical problems are always hard. Like partially shorted transformers, bad panel meters, none repairable switches for Funke and Neuberger. All kind of things that were impossible fix by the previous owner makes the thing land on Ebay. The seller always tries to appear the untechnical Mr. nice guy, so he wants to put you in the 'lucky' position. Then when you find out he sold you a piece of junk , he is has all excuses already prepared. The Ebay text was formulated with great care, and in the you end up as the 'unlucky' guy. Reality is often, the seller has been trying like mad to get it fixed, and gave up on it. Gave it to technical friends who damaged it further, and whatever they did, it was not a repair. With the crazy prices on Ebay, he just sells it, and buys another one for the same money. WIth a few tries he can be lucky. So he can't go wrong. And nooo... I am not paranoia. You have to read those Ebay adds with a sharp eye for detail. Just look at the above picture. What animals do you see there? A cat and a mouse? It's a cat and a hamster.