General part about AVO tube testers

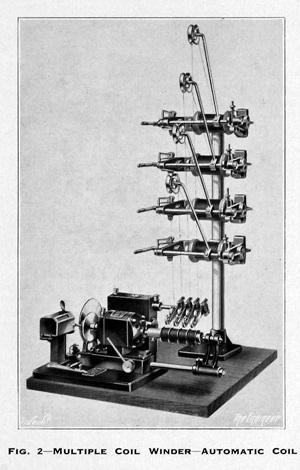

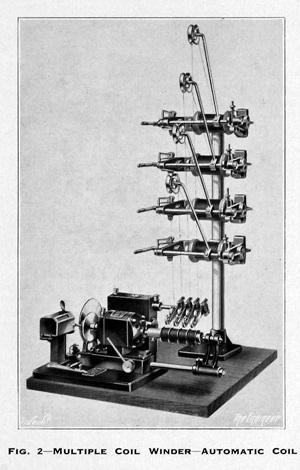

The AVO company was founded in 1923. They have been buying and selling parts of their business, but in the end were bought themself by the 'Megger' company. So they were absorbed. Originally they were selling coil winders. I do not have all details on their history, but the buying and selling included a panel meter company, and also the Taylor company. They have made very many precision instruments, including transistor testers, but the most profitable testers was their AVO8 multimeter, which has seen many redesigns, ending in a version with laser tuned resistors. When I was doing my electronics studies, there were many of the AVO8 still in use. Teachers said we had to learn to use them, because anyone can measure with electronic meters, but measuring precise with an analog meter, which pulls it's own energy from the circuit, needs much better understanding of electronics and of what you are doing. The AVO company was founded in 1923. They have been buying and selling parts of their business, but in the end were bought themself by the 'Megger' company. So they were absorbed. Originally they were selling coil winders. I do not have all details on their history, but the buying and selling included a panel meter company, and also the Taylor company. They have made very many precision instruments, including transistor testers, but the most profitable testers was their AVO8 multimeter, which has seen many redesigns, ending in a version with laser tuned resistors. When I was doing my electronics studies, there were many of the AVO8 still in use. Teachers said we had to learn to use them, because anyone can measure with electronic meters, but measuring precise with an analog meter, which pulls it's own energy from the circuit, needs much better understanding of electronics and of what you are doing.

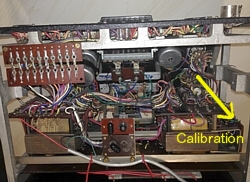

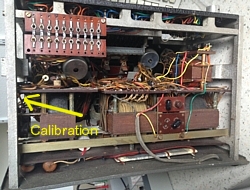

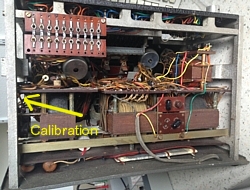

Calibration

Help! My tester seems uncalibrated!

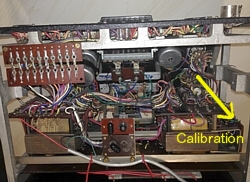

For calibration, the manuals say you need to measure the Anode and Screen voltages with an AVO8 meter. This meter gives some load to the circuit, and the voltage drop is included in the test values, as AVO writes. Though I have to say, that voltage drop, I can not see it.

It is much different with the grid voltage. That has to be measured with a tube voltmeter, or today with a very high impedance electronic voltmeter. So not with the AVO8.

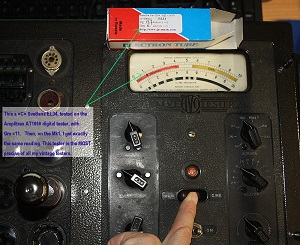

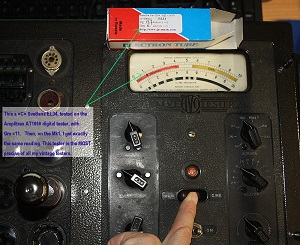

More important is, any modern meter, do t NOT use the more expensive RMS meters, but the cheaper, so called MEAN VALUE meters. RMS and Mean Value do not differ when we have a sine wave, but sine waves for the mains voltage is history. Today, the waveshape is heavily distorted, so when we talk about calibration, and measurement errors we do not want, we have to stay in line with the AVO patent, saying this works based upon average value. I prefer my good old AVO 8 for this, just taking no risk and doing things the right way. It was however quite an effort to find a good AVO8 meter. They are much sought after, and mainly crap is sold on Ebay. I had to send them all back. I noticed, most people bid very high on the latest models, but these are not the best! These have laser trimmed resistors, which was nice in those days, but they had not re-painted those after trimming. So the burn marks have now deteriorated and their values have changed. So you buy a mess almost by default. Moreover you can't take those newer ones apart as there are solderable foil PCB's in there, which are almost impossible to re-solder. So I got hold of the last model with untrimmed resistors (Welwyn panclimatic precision resistors) and normal wires instead of foil, and it was 100% good, the way I bought it. More information here.

Precision of the AVO testers

I do not have all numbers, but the plain, good old 1930 Valve Tester is very high precision, it's amazing. Provided it is good, and you do not buy somebody else's scrap and unrepairable mess.

Data of Mk1 and Mk2 I do not have. Mk3 and Mk4 work the same, and should have the same accuracy. In the Mk4 manual I found this:

- Anode Current measurement error: +/-10%.

- Transconduction measurement error +/-5%.

Given that anode current error is a composite error, 10% is very good. It adds up from small errors with all things that we need to use, like : Anode Voltage, Control Grid, Screen grid, Heater voltage, and panel meter error (Which I know is max 1.5%). Still ending up with 10% only, is a real achievement, and many Mk4 are not at the maximum limit of 10% but do a lot better.

What is outstanding, the Transconduction measurement error of only +/-5%, this is where most modern testers fail in a terrible way, when testing low current tubes. Such tubes like ECC83 must be tested at only 1.2mA. You may as well call that 1200uA. So at digital steps of 0.1mA, which is hard enough already, that alone is 8% error. So comparing a well calibrated AVO Mk4, with any expensive digital tester, and you see a difference? Well, the smaller the tube is, the more you can expect, the AVO is the winner. Reason for this outstanding accuracy, is the "backing off" system of such a measurement. Since we "zero" the meter before doing a transconductance test, we get in ONE step the result. Whereas all digital meters make two steps, thus doubling their own error. Which error is large already, with tubes like ECC83. It's hard to beat an AVO with this. Very hard. Only such testers which work with a test tone, will do better, because then again we have only a single measurement.

Around 1930: Valve Tester. With their famous 'Valve Tester' (see below here) their tube tester branch all started. AVO made it for many years. Around 1930: Valve Tester. With their famous 'Valve Tester' (see below here) their tube tester branch all started. AVO made it for many years.

Jump to Valve Tester

1948: Mk1. In 1958 AVO acquired the Taylor company, who had the famous (and today very expensive) Taylor 45 tester. This particular tester already used already the backing off method, to test for Gm. I don't know how they did that in terms of rights, but already in 1948 (when Mk1 was introduced) there was an improved version of the Taylor method used in the Mk1.To the Mk1, more or less everything was added, they could possibly observe on the market, and it was a real break through. Things like: Leakage and shorts test same as Funke, separate heater voltage transformer same as Hickok, Anode Current test same as Neuberger, A Quality Test, later included as as 'English Test' in many Hickoks, a safety relay with three functions, and probably I forgot to list a few features too. Socket pins were numbered by the normal standard, they put almost every tube socket in there, which possibly excited, and the comfortable roller switch makes operation quick and easy. There is even room to add one or two extra sockets. 1948: Mk1. In 1958 AVO acquired the Taylor company, who had the famous (and today very expensive) Taylor 45 tester. This particular tester already used already the backing off method, to test for Gm. I don't know how they did that in terms of rights, but already in 1948 (when Mk1 was introduced) there was an improved version of the Taylor method used in the Mk1.To the Mk1, more or less everything was added, they could possibly observe on the market, and it was a real break through. Things like: Leakage and shorts test same as Funke, separate heater voltage transformer same as Hickok, Anode Current test same as Neuberger, A Quality Test, later included as as 'English Test' in many Hickoks, a safety relay with three functions, and probably I forgot to list a few features too. Socket pins were numbered by the normal standard, they put almost every tube socket in there, which possibly excited, and the comfortable roller switch makes operation quick and easy. There is even room to add one or two extra sockets.

The Mk1/Mk2 has a very high range of specifications. These are:

- 400Volt anode and G2

- -100Volt on the grid,

- 100mA DC current for amplifier tubes,

- 250mA full load test, with a real dual rectifier circuit

- Every heater voltage, every mains voltage

- Test dual triodes with the flip of a switch

- Leakage in terms of Mega ohms directly, while doing so with high voltage.

The AVO Mk1 was the best tester available when it was introduced, and even today it is a very desirable machine to own. The German word for such a product is an egg laying wool milk pig :). You can take excellent advantage of everybody screaming like mad, to buy a Mk4, because Mk1/Mk2 is a wonderful machine just as well, and it had many specific differences with later Mk3/Mk4, which are not disadvantages. The Mk3/Mk4 contains a lot of face lifting, which sure looks nicer, but it is not a better tester. So nothing against Mk3/Mk4 of course, bit you would make a terrible mistake calling Mk3/Mk4 the machine which solves the "problems" of Mk1/Mk2 and have better accuracy. Because both these things you are not getting with Mk3/Mk4 at all. But with Mk3/Mk4 you do get the trouble of broken meter risk, a lot less convenient to use, less easy to service, and missing the white scale backlighting of Mk1/Mk2. Mk4 even misses the red "shorts" warning lamp. For that, you get the nicer looks of Mk3/Mk4, and the hype you have the "best" there is. In addition, when it turns you on, you get the fake precision illusion of the Mk4 dial wheels. If you ever had to repair a Mk1, and take the hood off, like a jacket, you may think this is a normal and good way to design something. Well, then try to repair something inside a Mk4, you can't really open it. Because unlike Mk1/Mk2 it has no chassis. So the aluminium bottom plate holds everything together, which is fine as long as you don't need to do any repairs. There are many places and things inside Mk3/Mk4, which you can simply NOT reach. Like the row of rotating switches at the bottom From the side panels, you can work a little bit under 90 degrees inside, but you will not be able to work in the center of the tester that way. I agree it is probably not needed, but probability always works that way, such testers are the ones that are sold on Ebay. So "not needed", don't count on that. I have seen them often with contact oil sprayed all over. The AVO Mk1 was the best tester available when it was introduced, and even today it is a very desirable machine to own. The German word for such a product is an egg laying wool milk pig :). You can take excellent advantage of everybody screaming like mad, to buy a Mk4, because Mk1/Mk2 is a wonderful machine just as well, and it had many specific differences with later Mk3/Mk4, which are not disadvantages. The Mk3/Mk4 contains a lot of face lifting, which sure looks nicer, but it is not a better tester. So nothing against Mk3/Mk4 of course, bit you would make a terrible mistake calling Mk3/Mk4 the machine which solves the "problems" of Mk1/Mk2 and have better accuracy. Because both these things you are not getting with Mk3/Mk4 at all. But with Mk3/Mk4 you do get the trouble of broken meter risk, a lot less convenient to use, less easy to service, and missing the white scale backlighting of Mk1/Mk2. Mk4 even misses the red "shorts" warning lamp. For that, you get the nicer looks of Mk3/Mk4, and the hype you have the "best" there is. In addition, when it turns you on, you get the fake precision illusion of the Mk4 dial wheels. If you ever had to repair a Mk1, and take the hood off, like a jacket, you may think this is a normal and good way to design something. Well, then try to repair something inside a Mk4, you can't really open it. Because unlike Mk1/Mk2 it has no chassis. So the aluminium bottom plate holds everything together, which is fine as long as you don't need to do any repairs. There are many places and things inside Mk3/Mk4, which you can simply NOT reach. Like the row of rotating switches at the bottom From the side panels, you can work a little bit under 90 degrees inside, but you will not be able to work in the center of the tester that way. I agree it is probably not needed, but probability always works that way, such testers are the ones that are sold on Ebay. So "not needed", don't count on that. I have seen them often with contact oil sprayed all over.

Mk2 Electrically this is face lift version of the Mk1, but there is little difference.

Ease of use

Both Mk1/Mk2 are more convenient to use, and to service than Mk3/Mk4. What speaks in advantage of Mk3/Mk4, is slightly more precision with larger size tubes, though this difference is small, and you may not notice it. What is nice, is the rugged case of Mk3/Mk4, and sure the lovely looks. Still I think performance / Price ratio of Mk1/Mk2 is a lot better.

With Mk1/Mk2, after backing off, you can switch back and forth between Plate Current and Gm, simply by a switch. Folks... this was SO WELL DONE. With Mk3/Mk4, this comfort is gone. In case you want to flip from Plate Current, to Gm reading, this is NOT possible without doing backing off every time. Which I find extremely annoying. Also the backing off with Mk1/Mk2, is done with one knob only, and is fully stabile. The Mk3/Mk4 uses two knobs, and still that works not always good. So think well, with some of the special features of Mk3/Mk4, what exactly these are, and if you are really in need for this, and if that is worth to you the more difficult operation and higher price.

Jump to Mk1,Mk2 part.

1955: Mk3 was introduced at a price of 60 British Pound. Thought it weighs 35 Pound. They put the Mk3 in a rugged, futuristic housing which even today looks fancy, and that is of course part of it's collector's value. The disadvantage of the new housing is, by itself this is the chassis, so you cannot take it off as with Mk1,Mk2. Also you can also not remove the bottom. In case you do have larger service jobs, the higher weight and lesser accessibility of the Mk3 makes it harder. A major change with Mk3, was the option to test very high Gm tubes of a special kind, as found in some TV's. For HiFi, such tubes were not used anyway. This advantage however, was paid for with more complex method of Gm measurement. So less comfort as with Mk1/Mk2, and you get little advantage in return. Take this well into account when you can't decide between Mk1/Mk2, and Mk3/Mk4. 1955: Mk3 was introduced at a price of 60 British Pound. Thought it weighs 35 Pound. They put the Mk3 in a rugged, futuristic housing which even today looks fancy, and that is of course part of it's collector's value. The disadvantage of the new housing is, by itself this is the chassis, so you cannot take it off as with Mk1,Mk2. Also you can also not remove the bottom. In case you do have larger service jobs, the higher weight and lesser accessibility of the Mk3 makes it harder. A major change with Mk3, was the option to test very high Gm tubes of a special kind, as found in some TV's. For HiFi, such tubes were not used anyway. This advantage however, was paid for with more complex method of Gm measurement. So less comfort as with Mk1/Mk2, and you get little advantage in return. Take this well into account when you can't decide between Mk1/Mk2, and Mk3/Mk4.

Jump to Mk3 part.

1958: Mk4 This is a face lift of the Mk3. Electrically it gives the same performance. Mk4 has no more tubes inside, so it is all solid state. Also it features gear wheels in the Grid voltage and Gm dial wheels, but for operation and precision, there is no difference, as precision is not limited by the fine gear wheels, but by the whole working principle, and that is the same. So when I set the grid at -2Volt with Mk3 it is directly on -2V. With Mk4 there is a 1:20 or so gear on the potentiometer, but inside it's the same 1 turn pot meter as the Mk3 has. So the precision doesn't get better from it, it just feels and looks better, though myself I need a lamp now to peep inside that hole of the Mk4 when the grid voltage is displayed. Perhaps your eyes are better, but I cannot read it conveniently. With Mk1/Mk2, Mk3, I can read it better. 1958: Mk4 This is a face lift of the Mk3. Electrically it gives the same performance. Mk4 has no more tubes inside, so it is all solid state. Also it features gear wheels in the Grid voltage and Gm dial wheels, but for operation and precision, there is no difference, as precision is not limited by the fine gear wheels, but by the whole working principle, and that is the same. So when I set the grid at -2Volt with Mk3 it is directly on -2V. With Mk4 there is a 1:20 or so gear on the potentiometer, but inside it's the same 1 turn pot meter as the Mk3 has. So the precision doesn't get better from it, it just feels and looks better, though myself I need a lamp now to peep inside that hole of the Mk4 when the grid voltage is displayed. Perhaps your eyes are better, but I cannot read it conveniently. With Mk1/Mk2, Mk3, I can read it better.

Also left out (VERY unfortunately) is the lamp backlighting of the previous models. It was real backlighting, so through the whole meter, the scale is transparent, and from behind is a window. This was simply beautifully done with Mk1/Mk2, Mk3, and i love it.

Besides, there is the red 'fault' lamp of the Mk3 was also left away, because the Mk4 meter is not transparent anymore. This was really impressive when you make an error with the older Mk3, and the tester goes into fault mode. The power is switched off, the tester buzzes at you, and a 25Watt red lamp burns from behind the meter very bright. Mk4 has only the buzzer and power off.

The diode rectifiers and Selenium Rectifier, were replaced by silicon rectifiers in the Mk4, which may seem an advantage, but in reality the silicon diodes of the Mk4 can damage, and the diodes of the Mk3 will survive some foolishness.

In favor of the Mk4 is they moved the service panel from the bottom to the left side panel. This is really an major improvement. Also there is some theoretical improvement in test results, as the Mk4 has works with a half sine wave testing the tubes, whereas Mk4 puts a full sine wave on the anode and G2. This should make no difference, as during reversal of the signal (so negative anode voltage) the tube will cut off anyway. The Mk4 system is a bit more elegant, but as said, I found Mk4 not work better because if that.

Without the meter back lighting , and more difficult way to read Vg and Gm number inside a peep hole, as in the Mk4, I prefer myself actually the Mk3 above M4k!

Though most people see that different, and Mk4 prices are a factor 1.5 or 2 higher.

Jump to AVO Mk4 part.

VCM163 This tester features mainly the oscillator method for Gm. So not only the nasty backing off procedure gets obsolete, but also the oscillator method by nature is the most precise there is. This reflects greatly with the measurements. Also now, there is no more compromise needed, to measure plate current as well as Gm with the same circuit. So I find Plate Current measurements more precise with VCM 163, and Gm measurements are flawless because that is now a real analog measurement with an oscillator. However, VCM163 misses all older sockets, and features some futuristic 10 pins sockets which they expected to be a break though. That did not happen, and the tester can't test any UX4 tubes. You can actually add this socket conveniently. VCM163 This tester features mainly the oscillator method for Gm. So not only the nasty backing off procedure gets obsolete, but also the oscillator method by nature is the most precise there is. This reflects greatly with the measurements. Also now, there is no more compromise needed, to measure plate current as well as Gm with the same circuit. So I find Plate Current measurements more precise with VCM 163, and Gm measurements are flawless because that is now a real analog measurement with an oscillator. However, VCM163 misses all older sockets, and features some futuristic 10 pins sockets which they expected to be a break though. That did not happen, and the tester can't test any UX4 tubes. You can actually add this socket conveniently.

Jump to VCM 163 part.

The 'VALVE TESTER'. The 'VALVE TESTER'.

Also called "2 Panel Valve tester.

This is the mother of all AVO's. Erroneously referred to as Mk1. Also by myself, I am correcting this where I see it. So this is not a Mk1! Old, but fully up to date - it can still test EVERY tube, when only the socket is added.

I own two of them, and I admire the craftsmanship of the designers. Add to this the very good build quality of the inside parts, but also the deck itself and the panel meter. When I first saw only pictures of them, I thought this can not be interesting. It looked too old, too primitive. I own two of them, and I admire the craftsmanship of the designers. Add to this the very good build quality of the inside parts, but also the deck itself and the panel meter. When I first saw only pictures of them, I thought this can not be interesting. It looked too old, too primitive.

Then I could buy one, which the previous owner built into a beautiful custom made nice metal case, with a drawer in it. He made really a nice product from it. I saw it on a ham market, and I thought at first, what AVO is that? Then I realized what this man did, and I felt sure he would only make that effort if the tester itself was in very good condition.

Well I made no mistake:) It's the star in my collection. The Avo Valve Tester has some resemblance with the Mk1....4, and the main difference is you can also see not see the anode current with the the valve tester.

The "quality" measurement works the same way (the good/bad scale) both electrically and in terms of operation.

The Gm measurement works the same too, but the Valve Tester is more comfortable with this, because you don't need all those many steps as with the later Mk1...Mk4. When you operate the valve tester, the first and only thing you do, is the backing off. Then you already can press the mA/V switch, and the result appears on the meter. Those of you who do have a Mk1....4 will know how many steps that is, before you finally have the mA/V on the meter.

What increases the comfort also, you don't need to set the grid voltage. There IS a grid voltage used inside the tester, and it's method to produce this voltage was directly used in the later Mk1....4 as well. Just it is only used to set the meter needle to zero. So the whole setting procedure is done with one knob only, and the only thing you need to do, is zero the meter. (Called "set zero")

Moreover, the mains calibration (as with Mk1....4) is not needed. That saves work for the tester operator, but also there is a very nasty calibration point of the Mk1....4 here with this, which the "Valve Tester" also does not have. The mains voltage itself is set in steps of 10V, by opening up the tester. So that's a one tine adjustment only. Then, for the rest, the "set zero" adjustment takes indirectly care of this too. So by this, you calibrate actually the whole tester, before you begin.

So the quick procedure and easy of operation is unique with this tester. It is the fastest parametric tester I know of.

Though it does have a very fast heater to cathode leakage test, it has no quick shorts test. You can test for shorts however, but it's done by cable plugging. For this, you need to plug in two plugs into the holes below the on-off switch. Behind one of the plugs is also a switch, which is operated by the plugs itself. This connects the panel meter lamp plus a test circuit to the plugs. These two plugs provide the shorts test. When you connect them together, the neon lamp will burn, and the lamp goes off below at appr 500k Ohms. The tubes electrodes can be accessed via the socket board, it has plug holes for that. Admitted, this is not really convenient, but it can be done. Most digital, new made testers have no shorts test at all, and I hear nobody complain about this.

It does have a very good and convenient cathode to heater leakage test. Just a flip of the switch, and you can read it directly in Mega ohms. Older versions use the tube under test also as the rectifier device, later versions have an additional Selenium diode for that. Either way it works.

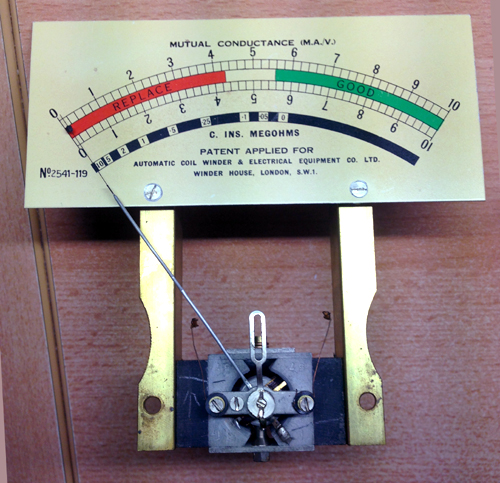

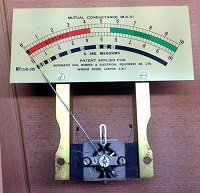

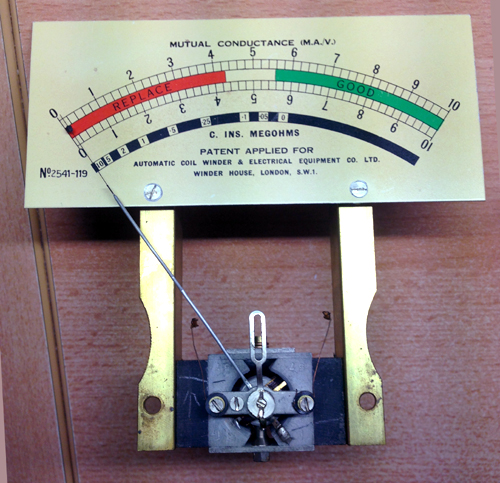

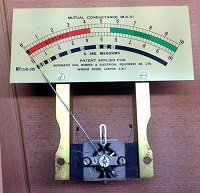

The panel meter is very pleasant and it reads precise from this large scale of course.

Inside is almost no electronics, and the values of the carbon resistors is not critical. All critical resistors are wire wound from 'Eureka' wire, today called "constantan" wire. No calibration is needed, not much can be off value. The only thing which can be off value is the meter sensitivity due to loss of magnetism. For this there is an (appr) 50 Ohms series resistor in the meter circuit, and it's the only factory calibration the tester has. The meter itself is from 0.6 ... 0.8mA and together with a combination of the 50 Ohm series resistor and a 9 Ohms shunt resistor, the assembly meter + two resistors must be 1mA. In the factory manual ) is described how to test this. So not the meter itself must be 1mA, but the assembly.

Here is the procedure to check the meter assembly: Manual1 - Manual2

I tested a 6SN7 that I know has exactly 2.7mA/V at 250V / -8V. The Avo Valve Tester reproduces this value accurately. I want to investigate it better, to see how they get this precise results from just two transformers and some resistors. It is the mother of all other AVO's. If you are buying a tube tester, this is one of the few that you can buy with little risk, when it is in nice condition. Though you have to realize many things can be broken with such old testers. So ask some reasonable questions about it's condition. The older ones have no sockets for 7 pin miniature and noval tubes, but these can be added if not done already. Or some have adapters with it. You can also remove a useless socket, and mount it in there. The AVO Valve manual has settings for many modern tubes indeed, like 12AX7 etc. That's what we call good software updates! Unlike the modern Amplitrex, they update nothing. So you are actually quite up to date with this (1930 or so!) AVO tester.

Since the AVO VALVE TESTER is very old, you need to get one with very nice optical condition. Otherwise changes are too high you buy one that is detoriated. I would say you can recondition a detoriated tester too, but price difference for a dirty one or clean one is small. So you are far better of with 50 Euro additional for a clean one, and leave the dirty ones for the gold diggers. The extra 50 Euro is well invested.

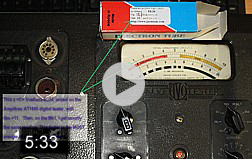

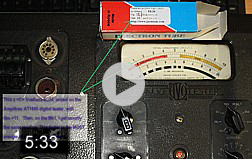

This is a video, demonstrating the use of the AVO Valve Tester. It shows the high accuracy of this tester, testing such a difficult tube as 6SL7. This tester can be used nicely to match such tubes even.

Let me know when you are interested to buy this item from me. I have just too many stuff here, and need to sell it before I die.

FOR SALE. "TWO PANEL" Tester.

ITEM 1.

This is the one pictured above. I hope you can view the above video. If not, download the . mp4 file to your hard disc at some location, and view it from there. A very talented metal worker build a dedicated metal case for his two panel valve tester, He did this so beautiful, used vintage hammer paint, and even made a metal drawer at the side, to fit the accessories. And of course there is a normal IEC connector used. Which cable you can unplug an put in the drawer as well. If you do not know this was actually made from a set of two-panel meters, you will not believe it. I bought this item at a ham show, and I thought at that moment, it was some unknown AVO model. It looks as if it was intended this way by AVO, and it solves what I find so nasty about the two-panel meters: It has two panels. So now it has become one tester with one deck. This one is fitted with the modern sockets, such as 9Pin Noval, but still has all vintage radio sockets as well. The reading is fully accurate, and technically it is in 100% good, and perfect condition. There are no cracks on the roller switch and it runs good. The meter has no sticky position, and also finds the zero position smooth and exactly. This is not only an extremely beautiful collection item, it is a great tube tester as well. It works absolutely correct , and precise. PRICE 600 Euro.

ITEM 2.

This video is from another 2-Panel tester, which was sold, but you can see how they work. download the . mp4 file.

This one is for sale: Few pictures here, but I can provide more if needed. This tester needs some work, but it is of the kind everybody can do. What needs no work is the part with the meter. I have restored and cleaned the panel meter itself, also cleaned the scale, which came our like new from behind a layer of dust. I re-glued the glass, adjusted and verified all internals, lubricated and cleaned the switches. There is nothing any more which needs to be done, it is all good and working fine.

As you can see, the panel meter itself is rust free. Look at that old fashioned horse shoe magnet. Such are not small size, but very stabile, and have a very uniform field, because the ends are flat. Note, at the front, is the magnetic shunt. This is just an adjustable piece of iron, with brass screw, and the iron shunts the magnetic gap. So when put nicely in the middle, the gap is maximum shunted. When you shift it too one side, or even totally remove it, the magnetism inside the gap it at it's highest. As you can see, it is in the middle, so in the (unlikely) case the magnet would loose some magnetism, it could conveniently be compensated.

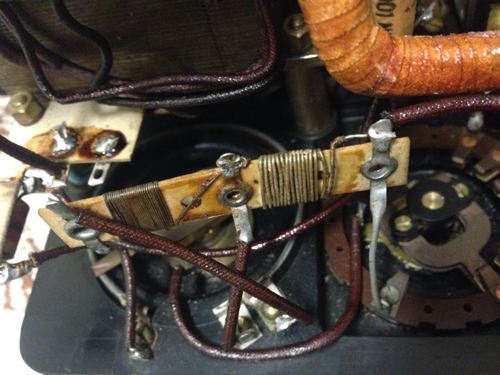

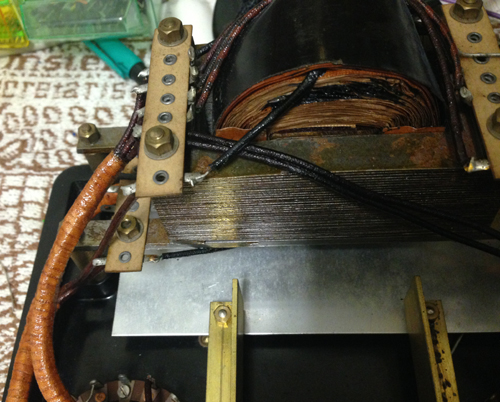

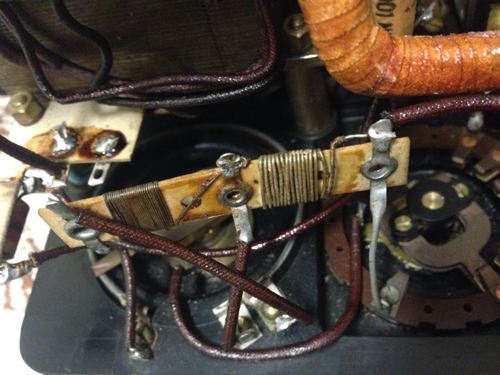

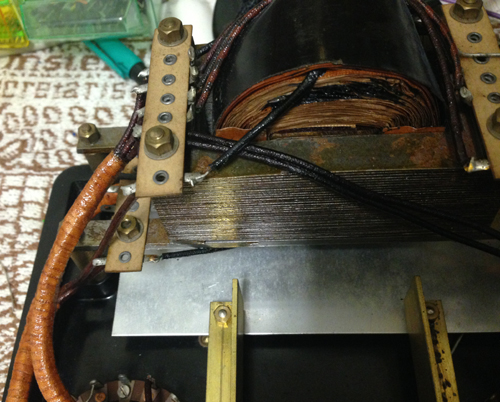

This is the mA/V pot meter. It features two resistor paths, which are different value, and these are serialized by the arm. Like this, an logarithmic behavior is simulated. Also, like you can see from the larger picture, the outer wire is made of two parts, a thick and a thin wire. So this pot meter if broken has to be repaired, but because you can not replace this by something else. I noted the windings were a bit loose inside, wiggling each time I rotated the pot meter. The original potting mass was brittle. So eventually they would have broken off the connection leads. To prevent this, I re potted this item with industrial two components resin. That worked out very nice.

This unit can be accessed from the side, so without opening the main case. The screw is set at 230V as you can see when you look closely.

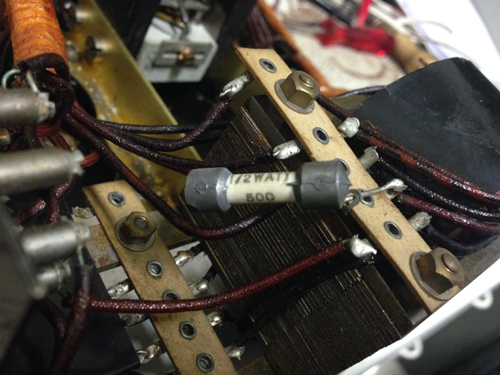

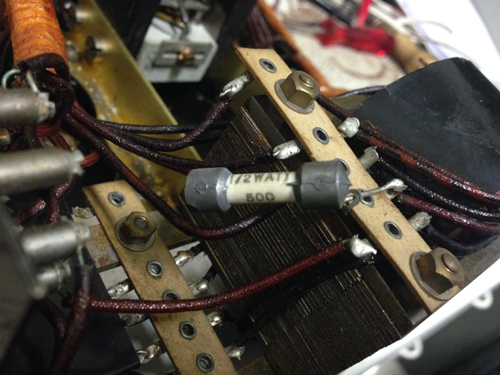

Ceramic Resistor from 1930. As usual with old ceramic resistors, the value is still correct.

These are the only two factory calibrations, which adapt the meter sensitivity to the required value. This is done with wire wound resistors. There is no user calibration for this tester, it is calibration free!

Switches as found in all instruments from that period. Large size, good materials, and you can take them all apart. Just, it is not deeded :)

Before and After cleaning with a tooth brush, and soap water.

This tester has a separate anode voltage transformer and heater transformer. There is no rust, and all solder connections are good.

Test result are correct and accurate. The knobs and scales around the knobs are very clean. All in all, this part is in wonderful condition. What needs to be done is only, the metal bottom needs a small repaint, it's not really needed, but it can use it, and is easy to do with spray, as the wrinkle paint is overall still good. You can take the metal bottom off, conveniently, and just spray it lightly with opaque black spray for cars. The part with the tube sockets needs some cleaning and painting. The contacts of the octal socket are a bit loose. Nothing bad, but I you need to take that original socket out f it, and then you can re adjust the clamp force of each socket contact. That is easy to do, but as said, you need to take the whole socket out. Also the roller switch operates quite t heavy. It will get quickly better after some use, but it will come back if unused for some weeks. I haven't done anything about it yet, because lubricating it from the outside may damage the printing on the wheels. It's in the original state from 1930. So it has to be taken out, and cleaned. Which by itself is very easy to do. The cable which connects the two panels was renewed, this was done technically good, but with loose wires, so not a stranded cable. It needs some sort of a jacket fitted around it. Sometimes you can find that. Last issue, there is some kind of 'bar' on the top of the thumb wheels. This is missing, but actually it works fine without it, and the previous owner never noticed it was missing. I hope I described this tester well, I would says it is a very good one. All nasty work, such as meter overhaul, deck cleaning, switches servicing, quite difficult potentiometer repair, and a few more things. it was all done by me. That is one thing. The other thing is, this tester works very good and accurate. Set for 230V, but you can change that easily to any voltage in steps of 10V. Also 110, 115V. This tester is ready to use.

Price 350 Euro.

Here is a nice picture, comparing the accuracy of the Amplitrex AT1000 digital tester, with an AVO 2-Panel tester. I get exactly the same reading. The camera was a bit on an angle, but when reading the meter from above it reads 11mA/V. Fully identical with the Amplitrex. Well how about that, with a 60 years old tester. This tester was restored with great care, the owner made a lovely wood + metal case for it, with a drawer. So he put the two in one case. I think he wouldn't have done so if t he tester was not 100% ok. Well it is indeed. Here is a nice picture, comparing the accuracy of the Amplitrex AT1000 digital tester, with an AVO 2-Panel tester. I get exactly the same reading. The camera was a bit on an angle, but when reading the meter from above it reads 11mA/V. Fully identical with the Amplitrex. Well how about that, with a 60 years old tester. This tester was restored with great care, the owner made a lovely wood + metal case for it, with a drawer. So he put the two in one case. I think he wouldn't have done so if t he tester was not 100% ok. Well it is indeed.

In a few words: A fully underestimated tester, secret tip. Sometimes I see people pay 200 Euro for some silly TC-2 useless tester. I don't understand it at all. Then you better pay this price for a Mk1!

Prices seen 2016: Dirty, unknown function: 170 Euro. Note: Even the broken ones offer the original AVO roller switch with socket unit, which would be the greatest tool ever when you build your own tube tester from a curve tracer kit. That means you can use the original AVO book for 10.000's of tube socket connections and test settings. So prices are hardly below 150 Euro as long as the roller switch is good. A clean and good working combination (so meter + socket unit) is worth a few hundred Euro.

Some final notes about repairing a broken VALVE TESTER

With a two panel valve tester some repairs are really difficult, like a fault in the flip switch in the middle. However that seems rare. Some other repairs are easy, such as a loose meter glass, loose wires, bad contacts. Many small issues which are just only service. Overall, when you are good at electronics, and prepared to learn how this item works, you can always repair it. But do not expect to start without any knowledge, and fix quickly on a Sunday afternoon that nasty problem, which two owners before you have failed to understand the cause. Also the Gm pot meter may be defective. I think you can always repair it, as long as you have the skills. When you don't have the patience, a broken pot meter is a killer factor, because it is an integrated part of the deck plate, and it has strange scale. With a two panel valve tester some repairs are really difficult, like a fault in the flip switch in the middle. However that seems rare. Some other repairs are easy, such as a loose meter glass, loose wires, bad contacts. Many small issues which are just only service. Overall, when you are good at electronics, and prepared to learn how this item works, you can always repair it. But do not expect to start without any knowledge, and fix quickly on a Sunday afternoon that nasty problem, which two owners before you have failed to understand the cause. Also the Gm pot meter may be defective. I think you can always repair it, as long as you have the skills. When you don't have the patience, a broken pot meter is a killer factor, because it is an integrated part of the deck plate, and it has strange scale.

Links:

FOUR STARS ****

AVO Mk1, Mk2. AVO Mk1, Mk2.

Ebay prices seen:

2006: Good condition: 800€. Defect: 300€

2011: Mint condition: 1300 Euro

2019: humidity damaged, for parts only: 454€

Specifications:

- Mains voltage 100...250V, 50 or 60 Hz.

- Leakage tests of every electrode, at high voltage (Appr. 90V)

- Leakage result in Ohms

- Heater Cathode isolation, tested hot or cold.

- Gas test with 10uA full scale

- Heater Voltage 1.1 ....110V

- Anode Voltage may 400V

- Screen Voltage max 400V

- Grid voltage 0...10V and 0...100V

- Anode Current full scale 2.5mA, 10mA, 25mA, 100mA

- Rectifier tests with real circuit, up to 250mA DC Output

- Gm: max 15mA/V (15.000mMho)

- Quality Tests by Hickok method

- Shut down protection relay for anode and screen, with memory function. (Must be re set after failure)

- Back lighted scale

- Sockets for almost every tube

Very Early Version, without Noval Socket. These testers have a Mk1 and Mk2 version, and I do not know the exact differences. When you have one like pictured here, it's a M1k for sure, but it is possible some other versions of the Mk1 existed as well. My impression is, the Mk2 is a version with more transformers, buy really exactly I do not know this. Very Early Version, without Noval Socket. These testers have a Mk1 and Mk2 version, and I do not know the exact differences. When you have one like pictured here, it's a M1k for sure, but it is possible some other versions of the Mk1 existed as well. My impression is, the Mk2 is a version with more transformers, buy really exactly I do not know this. |

It is difficult to see if this one already has a noval socket. For sure you need to check that when you buy one. It is difficult to see if this one already has a noval socket. For sure you need to check that when you buy one. |

Version with two Transformers. I think it is a Mk1. The Calibration Panel is on the RIGHT side, when seen from behind of the tester. Version with two Transformers. I think it is a Mk1. The Calibration Panel is on the RIGHT side, when seen from behind of the tester. |

Version with four Transformers. Can't say if it's a Mk1 or Mk2. Calibration Panel is on the LEFT side, when seen from BEHIND. The four transformer version seems the latest version. It sounds kind of unlogical they started off with a four transformer version, and then later found a good way to remove some transformers. Also if someone has only pictures, you can see that with this version the main voltage adapter is at 2/3 at the right side. Whereas what I think is an older version, so perhaps Mk1, has that switch in the middle. Version with four Transformers. Can't say if it's a Mk1 or Mk2. Calibration Panel is on the LEFT side, when seen from BEHIND. The four transformer version seems the latest version. It sounds kind of unlogical they started off with a four transformer version, and then later found a good way to remove some transformers. Also if someone has only pictures, you can see that with this version the main voltage adapter is at 2/3 at the right side. Whereas what I think is an older version, so perhaps Mk1, has that switch in the middle. |

This one I know only from pictures. It is a version with the book underneath, with FOUR metal handles, and with holders in the lid for cables. These seem to me some little step into the direction of the Mk3 design. My personal expectation is, this is a later version, This one I know only from pictures. It is a version with the book underneath, with FOUR metal handles, and with holders in the lid for cables. These seem to me some little step into the direction of the Mk3 design. My personal expectation is, this is a later version,

Note the nasty metal cable which attaches the book. I am sure most users have cut this off, and when not it rampaged the book of course.

Note, the original AVO Text underneath calls it a Mk2.

CALL for information. Please let me know when you have documented facts of any kind |

Documentation

Mk1 and Mk2 differ electrically quite a lot, but appearance and functionality is the same. Unfortunately there is little documentation around in the internet. The only complete manual I have seen, was copied by Mauritron UK. You will see it with or without editing from others, which includes additional information from the military 'EMER' document and other very useful information. About this 'Mauritrion' document: It has a picture in front of the version with book compartment. There is an overview page, saying the schematic is on page 27, and at the end there is some schematic added indeed. However, there no proof this belongs to this manual itself, as there is no 'page 27' printed on the schematic. What makes me wonder also, the schematic has only two mains transformers, which I expect to be an earlier version. However, the tester pictured in that manual (see below here) is the one with book compartment and four handles instead of only two. So to my logic this is a later version, which a contradiction. I think we have no good way at the moment to sort all of this out. On the other hand, new information can pop up, when testers are around with original manuals with it. I had that once with a Mk4, and I published the schematic of it, which version was unknown until then in the internet. So you see, this can happen easily.

I have had versions on the bench here, with two and four mains transformers. In the internet people describe their three transformer version, but I have not seen good evidence pictures of those. Do not confuse the Cut Out relay on the schematic with a transformer. What seems a transformer is nothing but a relay with two current inputs. (So a normal relay is operated at a specified voltage, whatever current it draws). The cut out relay is very large, and if you don't know what it is, you will think it is a small transformer. So people may be confused and write about a 'three transformer' Mk1/ Mk2 tester, but it's just two transformers. I don't know, but I would like to see better pictures of that.

I will try to categorize the versions here somewhat.

The late Hein Ros, was an expert on AVO documentation, and never was able to find the official factory service document. So chances it will pop up are low. Yet, the user manual as we have it, is extremely complete, and has a section on calibration. You will be able to service Mk1 and Mk2 with it.

The introduction of Mk1/Mk2

At introduction, this was the Rolls Royce amongst the tube testers. When this tester was the finest you can get in 1948, it still is today one of the best there is. Just they are very old, and need an overhaul to get them back in instrument condition again. With Mk1, all of the good technologies were combined. They had just acquired the Taylor company, and some remarkable details of the Taylor circuits went inside the Mk1. AVO did not have to ask anybody to wind transformers, they had their own facilities. Even today, the Mk1 is fully up to date. You have to add a noval socket if you have the earliest one, but really that's just soldering it in, as the tester was prepared for 9-Pin sockets from the beginning, and the tube data book was updated. So to add this socket, means just tie pin 1 of the Noval socket to pin1 of another socket, etc, and you can take the whole tester apart with just a few screws. So even today, when you use the (latest) Version 23 of the Valve Manual, you can test tubes of the latest kind. This tester had clearly the intention to be a no compromise product. Just name a requirement, and it will have it. It has a large variety of sockets. They can run on 50 or 60 Hz, from 100...250 Volts AC. It can test tubes for Plate current and Transconductance, up to a plate voltage to 400V, or grid voltage to -100V, plate current up to 100mA for amplifier tubes, and any heater voltage from 1.1 Volt to 110Volt. It can test rectifier tubes in a real circuit using a dummy load, up to 250mA. Moreover it features a build in quality test, which works the same as the famous Hickok method.

Since you have full control of everything you are doing, it is even possible to simulate quality tests as other tube testers are doing it. Such as the Funke W19 test method can be replicated, if you get yourself a pdf copy if their test cards, and if you understand how it's done of course.

Mk1/Mk2 do not differ very much in function or appearance, just Mk2 is the face lift version and the circuit is different. Comparing Mk1/Mk2, with Mk3/Mk4, I would say the Mk1/Mk2 is more down to earth. Yet offer the same functionality. If you can do without the fancy looks of Mk3/Mk4, you get the same results, and Mk1/Mk2 is easier to operate, faster, more logical, and the case is lighter weight.

The housing of Mk1/Mk2

Well it's just the housing, but I do want to say, they are more convenient to do maintenance on than Mk3/Mk4. You can just lift off the complete outside housing like a jacket, by only remove fours screws. Unlike Mk3/Mk4, you can also take the bottom off, and the internal chassis is still protected by a frame, and very easy to handle. That is a very large advantage, and I have not seen this with any tester at all.

The housing is made from one plate of aluminum, which was folded such that it becomes a box. The edges were welded together and with great craftsmanship formed round, and brought into the final shape. Vertically the housing has a light V-Shape, to the top is 1cm less wide than the bottom. Probably they used a metal template, on which it had to fit on exactly, so they could slide it on an off. The case was painted with so called wrinkle paint, which is quite resistant against scratching, and it looks very nice too.

Because the housing and internal frame is of aluminum, the tester is relatively light weighted. There is also a disadvantage, the aluminum is not very thick, and it needs to be packed with very high effort when you ship it. So the usual, standard way like Ebay sellers pack it, will definitely end with case damage. However, that damage may be fixed with a wooden hammer, if you remove the case. Whereas Mk3/Mk4, do not damage easily, but if there is damage, it's much harder to repair, because you can't take them apart easily.

The meter of Mk1/Mk2

The meter is a 100uA type. Not as sensitive as the later Mk3/Mk4, meters, which have 30uA. So measurement of resistance leakage ends somewhere above 10 Mega Ohms. Given, all Hickoks, and other testers with a neon lamp can measure maximum use 0,4 Mega Ohms, you are still far better off. The performance with very low impedance tubes, at high current, is probably slightly more accurate with Mk3/Mk4. However, we talk about a small difference only, and still Mk1/Mk2, are excellent testers. To my opinion, Mk3/Mk4 are not worth their 2x higher market price, but markets are not always driven by logic. It's just how things are.

Like

all AVO's the whole tester works bad when the meter is bad, but meter of Mk1 is 100uA is more rugged than the 30uA meter of Mk3/Mk4. . Yet it can be defective, and a bend needle you more often find it, as not find it. So check out the meter, is the #1 action for an unknown tester.

The Mk1/ Mk2 metering is done different. With Mk3/ Mk4 you have a series resistor of 199 Ohms in the test circuit, and a very sensitive, high impedance panel meter is across this. Whereas with Mk1/ Mk2 rather the panel meter itself is low impedance. I think both systems have their own advantage. The specifications of the Mk1/ Mk2 panel meter is found officially nowhere. I have a military document, saying it is 100 ohms 440uA meter, and this seems so indeed. Only I cannot promise that is so with all Mk1/ Mk2.

How do these testers work?

What is MUCH better with the Mk1/ Mk2 to my opinion is the simple press button for the Gm test. So when you made some kind of mistake, you let go the button, and you are back to Plate Current mode again. With Mk3/Mk4, you need to rotate the test knob, back to plate current again, and that is just not as fast.

What is backing off? This is the AVO method, which they took from the Taylor testers, but AVO does it more straight forward. This is used to measure Transconductance directly in mA/V. It works very simple. Suppose you have a tube under test, with a Transconductance of 2mA/V at a particular setting of let's say 8mA. If you change the grid voltage 1 Volt, this will increase the plate current to 10mA. To make this possible, the meter itself (so not the tube) can be set to zero, just by adding a small voltage to it. The tube is still at 8mA. This step is called backing off. Now, you press the mA/V button, and you can read directly the transconductance. Logically this is on the 10mA scale, but you can change the scale, just as you like. Then, release the mA/V button, and go to the mA/V setting, press it again, and now you can read the quality of the tube on the good/Bad scale. Or, press now the 'gas' button, and read the Grid current directly in uA. When you practiced it a few times, you'll find it quick and logical.

Gas Test. There is no way what so ever, to measure the gas in a tube, after the vacuum pipe is sealed. So afterwards, we can only say it is very much or very little, and it is derived from the tube behavior. Gas is a pressure, and today expressed Pascal, and historically in Torr. There are a few ways to get a result, but generally when a tube has gas, it will also have grid current. (Positive, electrical current comes out of the grid. So electrons go in). Measuring grid current in the range of less than 500nA is difficult, yet defect level is around 1uA. A very simple method, is to add a resistor in the grid circuit, and there will be some voltage across it, when there is grid current like 2uA through 100k will give 0,2Volt. For some tubes, that is nothing, but other tubes will draw more plate current if the grid voltage is lifted slightly up (so less negative). So the common gas test in cheap testers works this way, it is only a resistor with a switch in parallel. However, this does not tell is the grid current in uA, also and it ignores the way the tube reacts to this small voltage. Like for a 300B you will see only 1.5% change, but for a 12AX7, 200mV grid voltage change, means 25% more plate current. At AVO they use a unique method. The tube itself is used as a measurement amplifier. The way they do it, is very clever. First, the tube is set up in a normal test. So a tube like 12AX7 is set up for say 1.2mA plate current. If it draws more or less, is not so important, as long as you are aware, you test grid current at that particular plate current. So it is better, to change the grid voltage such that the normalized plate current of 1.2mA is drawn. Now, the plate current indication is set to zero, by giving an offset signal to the panel meter. So the meter is now at zero, but the tube is actually at 1.2mA. No comes a calibration procedure (look here for details). So you need to do a few settings, which effectively uses the tube under test as a calibrated amplifier. After calibration, the meter is now 10uA full scale grid current. Press 'gas' and you have the result. It is really remarkable how nice this works, and also how they set up a 10uA Full Scale measurement, using a 440uA panel meter. Moreover, datasheets that do specify gas test results, always give this as uA grid current. Perfect - and this is exactly what we need. All AVO tube testers starting with Mk1 can do this. I will not say, there are no other testers capable of this, but myself I do not know one.

Faster results as with Mk3/Mk4, Part1. The difference is really significant, and I would like to pay some attention to it. With Mk1/Mk2, after backing off, you can DIRECTLY read transconductance on the meter scale. With Mk3/Mk4, cannot! There is a step in between, you need to adjust the Gm wheel until the needle is in the green center mark of the meter, and then you have to read Gm from the dial wheel. To me the Mk1/Mk2 procedure is a lot more logical, and faster too. Besides, reading Gm from a meter is nicer than reading it from a dial wheel. The fans of Mk4 calling this best tester from the Mk1....Mk4 series, are not wrong, but Mk1/Mk2 have this remarkable faster process, and I have to say, I prefer Mk1/Mk2 because of that.

Faster results as with Mk3/Mk4, Part2. What is also better with Mk1 /Mk2, is the backing off is done with only one pot meter, vs two pot meters in the Mk3/Mk4, where these often too sensitive against tapping. So you do the backing of, and right after it becomes already instable. If you just tap in the tester, you may need to do the backing off again. Also operating two pot meters is just tedious. With Mk1/Mk2, there is only one pot meter, which is actually internally combined of two pot meters. This makes it logarithmic, though wire wound. I have to say, this works much better! The backing off is done quickly and easy, and is immediately stabile. To my opinion, this is a large disadvantage of Mk3/Mk4, and Mk1, M2, does not have this. Owners of Mk3 and Mk4 will know, with two pot meters, you sometimes forget to set one of the two back to normal, that will bang the panel meter in the corner violently, if you begin a new test. You can do this wrong with Mk1/ Mk2 as well, but with only one pot meter, risk is lower. Add to this, Mk1 Mk2 doesn't react much less violently, and the meter is less fragile anyway. That explains why Mk1/Mk2 meters are normally still good.

Cleaning an old Mk1/Mk2.

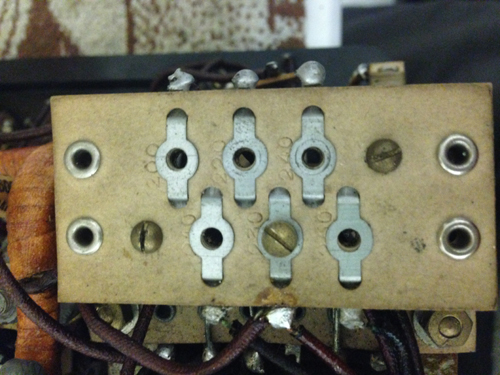

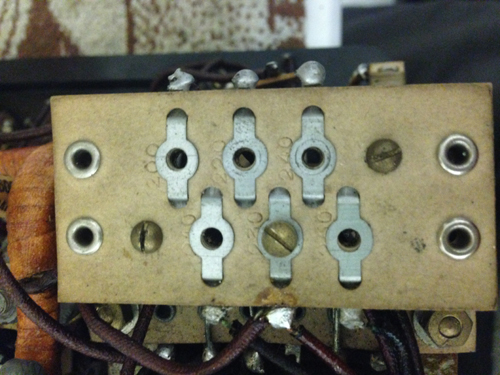

All sockets are tied together with their corresponding pin numbers, just as in the socket data book. From there is goes to the roller switch, and the outputs of the roller switch go to this soldering panel, pictured above here. Like that, the electrodes, so G1, G2, G3, etc, of a random tube, are always at the same position of this soldering panel. So the whole wire mess of sockets wiring and switching, is solved directly underneath the socket panel, and from there to the solder panel. From here, it goes nicely ordered into the tester. You can't say that from any other tester, and frankly the wire spaghetti is often is terrible to work on. Also you can remove the entire deck plate completely, for cleaning, which is the standard work I do with every AVO I get. Such simple things as a few drops of coffee inside some sockets can give you trouble, and also dust, which tends to combine with fungus over time, it not something you want to have in your socket panel. AVO is the only tester I know of, which can really conveniently remove the panel. I clean it with my own mixture of acid and soap water, and then with pure alcohol to wash out the water. After that dry it in an oven at 60 degrees, and I have an absolutely dirt free and leakage-free socket panel. I take off the roller selector for this, and clean it separately. All sockets are tied together with their corresponding pin numbers, just as in the socket data book. From there is goes to the roller switch, and the outputs of the roller switch go to this soldering panel, pictured above here. Like that, the electrodes, so G1, G2, G3, etc, of a random tube, are always at the same position of this soldering panel. So the whole wire mess of sockets wiring and switching, is solved directly underneath the socket panel, and from there to the solder panel. From here, it goes nicely ordered into the tester. You can't say that from any other tester, and frankly the wire spaghetti is often is terrible to work on. Also you can remove the entire deck plate completely, for cleaning, which is the standard work I do with every AVO I get. Such simple things as a few drops of coffee inside some sockets can give you trouble, and also dust, which tends to combine with fungus over time, it not something you want to have in your socket panel. AVO is the only tester I know of, which can really conveniently remove the panel. I clean it with my own mixture of acid and soap water, and then with pure alcohol to wash out the water. After that dry it in an oven at 60 degrees, and I have an absolutely dirt free and leakage-free socket panel. I take off the roller selector for this, and clean it separately.

Precision and Test results

WIth each newer model and version at AVO, precision has increased, and weaknesses have been eliminated. Yet, progress was only small, which is logical, because already the old 'Valve Tester' was a very good one. So don't think you buy 'old junk' when you buy a Mk3 instead of Mk4, or a Mk1 or Mk2. They are work comparable, and results are comparable too.

One difficulty AVO never talked about, is these testers are not good with very low impedance triodes, at high current. Such tubes are very few, and the error is seldom very large. Yet when you look up the 6080 in the valve manual, you find a small remark there: cannot be tested, due too low impedance. So that's the item. If you do test such tubes, at high current, there will be too much voltage drop over the current sense resistor, and even when just a few volts, the lower voltage tubes like 6080 will react on that, with quite a change of current. So effectively, the tube is tested at lower voltage as intended. The error from this is not small though with must such tubes, and the valve manual anticipates for that, by l test such tubes at higher voltage, and lower current. So at the same dissipation, and then everything will be fine. So to say it again, this is not an item to worry about. I am probably the only one who found this out anyway. A good Mk1 will make you just as happy as a Mk4.

Cleaning, repair and maintenance

People do not realize, but with Mk3/ Mk4, chances on buying one with a damaged meter is very high. With Mk1/Mk2, risk is a lot lower, because first, the meter of the Mk1/Mk2 can handle more overload, operation of Mk1/Mk2, is more logical and safer.

The maintenance when you buy one: The Mk1/ Mk2 is a much older tester, so they all need some work before you have them back into fine condition again. Yet, a Mk1/ Mk2, if all restored, can be your friend for ever. There is no maintenance, apart from calibration every 10 or 20 years. The rectifier are Selenium type. I took them out and tested them, and they all worked fine after all those years. There is general consense in the internet, that Selenium rectifiers are not good, and they warn for poisonous gasses when these get bad, and all kind of trouble. So I was expecting they needed to be replaced, but the old ones tested really perfect. No leakage at all, and very well defined 'on' voltage of appr 40V. I have a Tektronix 570 curve tracer for that, so I can perfectly test them. Yourself, you are advised to test them best way you can. Perhaps they can simply be replaced by silicon, but you need to check what that does to the voltages, and distortion of the wave shape. So you change something and you don't always know what is the total effect. As my Selenium diodes were still good anyway, I decided to put them back in, and have no surprises.

Service: Mk1/ Mk2 is very easy serviceable, because you can take off the whole cap with just four screws. So you can access it from all sides. Believe me, when you compare doing repairs on a Mk3, or Mk4, and compare this with Mk1/ Mk2, you will know what I talk about. Mk3 and Mk4 are not very convenient to work on, we have to say it. Though accessibility of components in Mk3 is the hardest. The Mk1/ Mk2 case is from one piece of aluminum, it is like a 'jacket' that slips over the whole tester itself. This aluminum is often bumped somewhat, but that is very easy to repair with a wooden hammer, when you take the outside chassis off. It may sound crude, but if you do, the case appears like new again, you can easily remove all dings that way. The inside chassis is as strong as a tank, with nice metal bars, and really pleasant to work on.

Check list for a Test sequence of a Triode:

The original manual has no quick set up, such as this little card which exists for Mk3. Mk4. So here is the procedure I use.

Note this: The switches have three rows. We begin at the top left. Then in the same order as reading a text, we end at the bottom right switch. Like this we can forget no switch.

- Switch off the tester, insert the tube under test. (DUT)

- Set the roller switch for the DUT

- Mains adjustment switch all to the right.

- mA/V to the 100% value for the DUT

- 'Set Zero' pot meter all to the right.

- Electrode Leakage all to the left, on the ~ Symbol

- Meter Selector to 100 in the outer scale. (That is 100mA)

- Circuit selector all to the left at Check(C). That means leakage teste with a cold heater and high voltage off.

- Bottom row, the anode selector to A1.

- Set screen Volt, Anode Volts, Neg. Grid Volts and Filament from the tube data book. Heater switch on the right must be at zero if unused.

- Set the multiplier for Vg accordingly 1x or 10x if not done yet.

- Switch on the tester. The scale must be backlighted. If not, press the Reset Switch, or check the fuse. If backlighted: continue.

- Adjust the meter for the ~ Symbol. Use the SET~ switch for that. If you have problems with the range, the tester may be set for the wrong mains voltage at the back.

- Now the tester is ready to begin with a few low voltage tests.

- Step the Electrode Leakage Switch clockwise, and observe the meter. At 'H' it must indicate a full short (close to zero ohms) indicating the heater is not open. At all other settings it must be high impedance. For amplifier tubes, skip D1, D2, that is for diodes only.

- Set Circuit Selector to Check (H). This will turn on the heater. Wait until it is nicely glowing, and repeat the previous step, this time with a hot heater.

- Set Circuit Selector to C h-k. This checks heater cathode leakage, here for the tube with cold anode still. This is an important test for noise, so don't skip it, specially not the hot part, which comes later.

- Now comes the High Voltage testing. Set the circuit selector to TEST, and Anode current should be indicated. Adjust the meter selector for a more sensitive scale. Wait until the tube becomes stabile, and read the anode current.

- Turn the Set Zero knob to the left, until the meter is at zero. Now press the mA/V switch and read the result.

- Optionally a Quality Test test can be done.

- Leave the Set Zero knob at the right position and set the Meter Selector to mA/V.

- Adjust the meter for zero with the Set Zero button

- Press the mA/V button. 100% Gm it will indicate in the center of the green scale.

- Optionally a Gas Test can be done. (Grid current test)

- Set up a normal tube measurement.

- Make the tube draw the normalized plate current, and leave that as it is.

- Set meter to zero with 'Set Zero' knob, while pressing mA/V button at the same time.

- Set meter selector to mA/V. Set meter to full range, with 'Set mA/V' knob, while pressing mA/V button.

- Release mA/V button, and press 'GAS' button. Full scale is now 10uA grid current.

- Set the circuit selector to C h-k. Check for no leakage, this time for a hot tube

- Set Circuit Selector to Check (H). Check for no leakage, this time for a hot tube. At this position, the meter may even turn to the left slightly, which is normal, indicating emitted electrons, even without voltage applied to the tube. In Check (H) position this should disappear after the heater cools down.

- Finish the sequence by setting the Circuit Selector to Check (C)

- Accidental Meter damage can result from leaving the tester at too sensitive range. To prevent this, after a test, set back the Set Zero Switch to the right position always.

Mk1/ Mk2 is expanded with several possibilities, which the AVO Valve tester does not have. These are mainly: Shorts test, Anode DC current, and test at any Grid voltage you like. Furthermore, the maximum anode and screen voltage was raised to 400V with the Mk1/ Mk2. (The AVO VALVE TESTER had maximum 250V). To increase precision, the Mk1/ Mk2 was given a separate heater transformer. So any heater current draw will not make the anode voltage drop. Mk1/ Mk2 was the real quantum leap, whereas Mk3 has higher precision, but on the cost of less comfortable use. Like Mk3 has one 'fine' and one 'coarse' pot meter for the backing off, and Mk1/ Mk2 has only backing off pot meter. Yet backing off with Mk3 / Mk4 is often difficult and overly sensitive when they get older, and this is often hard to fix. Even so it turns into a quality item for Mk3 or Mk4, so you want to know always: 'is the backing off still good?' Whereas Mk1/ Mk2 with only one pot meter can be backed off good enough, and for sure a lot faster as with Mk3/ Mk4. Also, testing of Gm and Gas, with the push buttons of the Mk1/ Mk2 seems more logical to me. Mk1/ Mk2 has a beautifully back lighted panel meter. So not just with a side lamp, but nicely with two radio scale lamps from behind, through the meter scale, which is opaque. Actually already Mk3 is missing the backlighting feature, and I can tell you this is really better with the Mk1/ Mk2. In case of a fault, with Mk1/ Mk2 the white backlighting goes off. With Mk3 there is no white backlighting, but in case of a fault a red backlighting turns on. I prefer the Mk1/ Mk2 method.

Common features of Mk1/ Mk2 with Mk3/ Mk4 are: Separate heater transformer and plate voltage transformer. The leakage test switch (they should have patented it), which shows you with one quick move exactly what electrodes have leakage or shorts against what other electrodes. A short is zero ohms, and leakage is represented directly in Mega Ohms, while tested with high voltage AC, yet limited in the uA range.

While tube testing, you can directly see the Plate current in mA. Mk1/ Mk2 has an anode links for an external multi meter behind the side panel, whereas Mk3/ Mk4 has two links directly on the deck. That is sometimes very nice to use.

Anode and Screen voltage up to 400 Volt. Plate current up to 100mA. So yes we talk about 40 Watts here. It can do any heater voltage, and any mains voltage. It features a protective relay with a hold function, and it has sockets for a remarkable large variation of tubes. We still talk about things that Mk1/ Mk2, Mk3/Mk4 have in common. Inside electronics are not fragile. Resistors and switches are good quality. No strange components, that you don't know what it's for. No bad resistors. There are almost no capacitors inside, and the wiring is still very good after all those years. No signs of cracks or anything.

What I like about the Mk1/ Mk2, it has one tube inside which only function is to be a reference tube. So the reference tube and the tube under test go into a Wheatstone bridge, where non-linearity of the tube-under-test is compensated with the non linearity of the reference tube inside. This method with the reference tube is very well done. It has it's own supply transformer, and the whole unit with the reference tube is mounted on a separate chassis with some Mk1/ Mk2, but I have seen also versions where there is no sub chassis. The sub chassis when present, has only four wires. Two are connected to the mains, and the other two are the connections at which a 'reference diode' is presented to the wheats tone bridge. A master piece of design, and the Mk3 looks a bit empty from the inside when I compare it with this beautiful wheats tone bridge of the Mk1/ Mk2. All in all, Mk1/ Mk2 sure is not the 'old tester' it may look from the outside. I really can recommend it. .

The grid voltage is set with a pot meter, and it has only two ranges: 1...10V, and 10...100V in steps of 1V. Mk3 has steps of 20 Volt, but... the first range is 0...20V. So for low grid voltage, Mk1/ Mk2 may seem better. Though with Mk3 this is compensated with a larger diameter dial wheel, and it comes down to the same. Yet setting for instance 1.2 Volts as you need of a 12AX7, works better with the Mk1/ Mk2 as with the Mk3. Also different with Mk1/ Mk2 is, you have a calibration pot meter for transconductance. Whereas Mk3 an Mk4 don't have that. I really have to say this here, that calibration of Gm with Mk3/ Mk4 is very difficult to do, as this is a factory calibration, no technician job for somebody later. Whereas with Mk1/ Mk2, there is just a simple and normal Gm calibration pot meter inside, and no factory calibration. So the previous owner cannot mess up the factory calibration of the Mk1/ Mk2 because it simply doesn't have any. So you see... don't underestimate the Mk1/ Mk2! This is really a good product.

Add a meter Protection network to your Mk1/ Mk2!

Capacitor protection. Look at the Mk4, they protect a 30uA meter with a 10uF cap and two diodes. I found 22...27uF is a maximum limit. At higher capacitance, the meter begins to interact with the capacitor, meaning it over shoots. In that case, when switching the current off, the meter goes into negative, before going to zero. This can be tolerated as long as it is not too much, and like this a larger capacitor can be chosen. I found a value of 350uF does this good. 8uF as recommended by Hein Ros, has absolutely no effect, and it is obvious he did not test that, but just picked that value from the Mk4 schematic. The Mk1/ Mk2 has a 460 or 440uA uA meter, and not just that, it is very low impedance. The meter I tested had 103 Ohms. In 1950, 305uF was a huge block, and not long time stabile. I think today's capacitors are fine for this application, and given the low impedance of the meter, some small leakage will not affect it. Yet of course, if you use such a capacitor, occasional testing of it, like every 15 years or so, belongs then to normal service. It is much recommended, because I have seem many meters damaged, with the needle being unbalanced, and then the linearity of the meter is bad, or it has a stick-slip problem..

Diode protection. Let me try to clear the biggest misconception of all, when using protection diodes. People use small diodes, to protect the meter. Like 1N4148 or glass Schottky Diodes, because from 1000 people, 999 think these diodes give lower forward voltage at lower current. This is absolutely WRONG. There is little point in trying to imagine how this must be, when you own a multimeter. In that case, you can measure it instead. I have to say, I was surprized to find very heavy Silicon Power diodes, across the 30uA meter in the Mk4. So I though at first, how primitive! Kick out that old fashioned junk, and replace them by nice 1N4148 glass diodes. Then, I compared forward voltage of those, at LOW current of 300uA, and much to my surprise it is a LOT lower with those fat power diodes. I thought, perhaps those were Germanium diodes, so I made a Voltage-Current plot with the Tektronix 576 curve tracer. But no, they were Silicon diodes. What was the conclusion? Those big rectifier diodes, I estimate them 6 Ampere types, have indeed the normal 0.7V at 6 Ampere, but 0.5V at 500mA, and even much lower in the mA range, and no measurable reverse leakage at just a few hundred mV. Whereas the tiny 1N4848 also has 0.7Volt, but in the range of mA already. So indeed, using a diode as a voltage clamp, works much better when the chip is larger. Which makes sense to me, because small diodes are just smaller pieces of the same wafer, from which the are cut. So a big diode acts as many small ones in parallel. I would say for the more rugged Mk1/ Mk2 meter, a 1N4004 diode is a good choice, and 1N4148 is too high impedance. |

AVO Mk3 AVO Mk3

Mk1/Mk2 was the quantum leap, it was the first 'big' tester which can do everything. Mk3 performs the same tests. The MK3 case was optically a big change, and precision was slightly better, but that difference is not very high actually. Moreover there is some loss in comfort with the Mk3, as with Mk1/Mk2 you can measure Anode Current and transconductance just by pushing a button. It has to be said, this great comfort got lost with the Mk3, and also with the Mk4 of course. Mk3 looks definitely nicer and the case is more rugged. However, for repairs, you cannot take the case off completely off, because it is a self supporting structure. So the more panels you take off, the more loose the construction gets, and it would fall apart. Whereas with Mk1/ Mk2 you can take the whole case off, like a jacket. This is really a big change with the MK3, the nice looking case, which is bullet proof, but you can't take it off. Also the board with the calibration pot meters on it, is reached a bit difficult. This board position was improved with the Mk4, but you can't take the Mk4 out of it's case also. Mk1/Mk2 was the quantum leap, it was the first 'big' tester which can do everything. Mk3 performs the same tests. The MK3 case was optically a big change, and precision was slightly better, but that difference is not very high actually. Moreover there is some loss in comfort with the Mk3, as with Mk1/Mk2 you can measure Anode Current and transconductance just by pushing a button. It has to be said, this great comfort got lost with the Mk3, and also with the Mk4 of course. Mk3 looks definitely nicer and the case is more rugged. However, for repairs, you cannot take the case off completely off, because it is a self supporting structure. So the more panels you take off, the more loose the construction gets, and it would fall apart. Whereas with Mk1/ Mk2 you can take the whole case off, like a jacket. This is really a big change with the MK3, the nice looking case, which is bullet proof, but you can't take it off. Also the board with the calibration pot meters on it, is reached a bit difficult. This board position was improved with the Mk4, but you can't take the Mk4 out of it's case also.

Mk4 came after the Mk3. First be aware, the Mk3 and Mk4 differ not much. Mainly the Mk4 has a more 'fancy' way to set the dial wheels with a 1:20 gear, and Mk4 has silicon diodes to generate the DC Voltage inside, where M3 has tubes and Selenium rectifiers for that. That is all. However, the tubes and Selenium rectifiers of Mk3 I have never seen a case where these were defective, and the 1:20 gear of the Mk4 is just marketing, because behind that is just the same potentiometer as in the Mk3, and you can't set it more precise by adding a gear to it. So frankly, consider Mk3 and Mk4 quite the same.

About the Mk3 now. This tester looks different, but similarities with Mk1/ Mk2 are many. The face lift is the case itself, nicer arrangement of the knobs, and nicer looking knobs with plastic dial wheels for the grid voltage and transconductance. Also the case is now idiot proof, which is a great advantage for the average user, and of course for the transportation experts of the post office as well. Mk3 has the more sensitive 30uA meter, which is a advantage and a disadvantage. The advantage is, the 30uA meter allows 3x better sensitivity with leakage test. This makes the Mk3 such a sensitive device, you can even use it for transformer or cable leakage tests, when you know how to do it. These meters However, are the 'standard' problem with Mk3 and Mk4, as the tester is probably used in it's 70 years of existence by many people, There have been always one or two who were not interested in what they do. If you want to find out by trial and error how this tester works, that's the beginning of trouble. Leaving behind a still working meter, but with linearity errors. Any meter damage can be not seen quickly from the outside, or derived from it's function easily. Somebody will notice at some point the tester is inaccurate, and begins to calibrate it, with a bad meter inside. However, there is no way, to make a tester work good, with a bad meter inside. So eventually the tester gets put aside, often for a few decades, and then gets sold on Ebay, 'as is'.

Such meter problems do exist less e with Mk1/ Mk2, as these have a 100uA meter, which is more rugged build.

The panel metering system.

This is a big change compared to the Mk1/ Mk2. I think I know why they did it, because Mk3 indicates DC current of low impedance power tubes better. This is really the change Mk3 offers. The meter of the Mk1/ Mk2, is a very low impedance meter, and Anode current flows for a great part through the metering system itself. Whereas with Mk3 there was used a copper wire wound current sense resistor of 199 ohms, and the voltage across this resistance is measured to determine the plate current. As you can see, voltage across 199 ohms is very low at 1mA only. So the panel meter of Mk3 needs to have very high sensitivity. The panel meter is 30uA full scale. Which at those days was a masterpiece of meter design, and today it is even more, as most factories that can make high quality meters, have disappeared. The Chinese still sell cheap 30uA meters, but these have too high impedance, they're not very good in reality.

How did they increase the meter sensitivity?

Well, one way is to make the circular hair springs very fragile, and low force. However, this makes the meter problematic with respect to dirt particles, friction and electrostatic loading of the needle paint and glass. Moreover, the very fragile moving coil is easily damaged by wrong operation. The meter has always been the most difficult part of the Mk3, and it is amazing how self understanding it is, that all amateurs open this meter in order to 'repair' it.

Temperature compensation:

The current sense resistor of 199 ohms is copper wound in order to have no temperature effects, as copper has a very high temperature coefficient. This sound like a contradiction, but it is not. Because the wire of the meter coil, and the calibration resistor inside the panel meter, is copper wound too. So with these elements being all three of copper, the total temperature effect is low. The current sense resistor will burn out sometimes, when people put 250mA rectifiers under permanent test. Then after half an hour or so, the isolation burns, and some windings may short. A repair should be done with normal copper wire. So do not replace this 'strange' resistor with a nice ceramic precision resistor, in an attempt to 'improve' it.

Buying advise:

The dial wheels should not be badly repaired. Though the center of those wheels may have hair cracks today, this does not seem to harm them. In case you do need to replace one of those wheels, you can make one yourself from a knob of any other AVO Product. Sometimes you see some kind of old AVO products on Ebay for 30 Euro only, and you can take off one of the knobs. Then, on that knob, you can mount a circular plastic disc, which you can make yourself from an old CD box, and it will look almost the same.

Beware for a defective meter.