Since 1993 Copyright Notice

Tube Amplifier Kits

300B or 300B-mesh Classical Amplifier full description. Revision H.

This design has been build several times. When ordering materials, you get 10% discount. This can be when you order it all together, or when you order some parts later too. This is not done automatically, so please ask for it when ordering and it will be processed with 10% discount.

This beautiful housing was made by Anastas Kilda from Lithuania. Please note, you need to build a housing yourself.

Please read some more feedback here.

Resistors we don't sell. Capacitors only when there is an order number for it, in the parts list (all below here). Though not on the parts list, consider the transformer caps from Lundahl, these are from magnetic shielding steel, and also these caps can be opened while mounted, and you can work or measure on the wiring. They're really convenient, and very good looking transformer caps, powder painted so they won't scratch, and with decent Lundahl logo on it. |

A potentiometer is used at the input of this amplifier. Of course it can be removed if when you don't want to use it. In that case it is recommended to change the grid resistors on pin #4 of the 6SN7#s to 10k. However, many pre amps today produce far to much signal, so it may be a good idea to have a volume control on this 300B amplifier. Like this you can adapt the amplifier's sensitivity for maximum output signal at '100%' volume at the pre amplifier. First, this will give more convenient volume control at the pre-amp. Also, this will reduce the overall noise of the system, when the preamplifier is of a somewhat noisy type, which can be the case with tube pre amplifiers. This method of noise reduction really works, and cost only a potentiometer. |

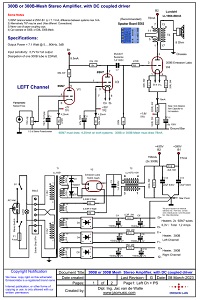

The pre-amp and driver circuit of this amplifier is a classical one, as can be found in several historic amplifiers in more or less the same way. The small capacitor of 15nF, was added by me to the first stage if the 6SN7, it expands the maximum frequency range a few kHz. Not much but for the small cost we can add it. It should be a foil capacitor of good quality, so to keep up with the impedance of the 470 Ohms resistor. What is interesting, initially I would have recommended for such a DC coupled circuit carefully matched tubes, but experiment (below here) show this circuit works well on every tube at all. In the 1920's a similar circuit was patented as the Loftin White. |

This is about the maximum the driver stage can do, before distortion comes in. Pictured here with 1kHz Triangle. (Triangle shows quickly if signal peaks are distorted ). This 1kHz signal is at 160 Volt peak to peak, which signal level is as much as the circuit can do safely. Above 180Vpp, it begins to distort. Tube was a 1960's 6SN7 (6H8) NOS tube, from Russia. The undistorted peaks at the bottom are only possible with a lot of emission of the tube. So it will saturate well. This is about the maximum the driver stage can do, before distortion comes in. Pictured here with 1kHz Triangle. (Triangle shows quickly if signal peaks are distorted ). This 1kHz signal is at 160 Volt peak to peak, which signal level is as much as the circuit can do safely. Above 180Vpp, it begins to distort. Tube was a 1960's 6SN7 (6H8) NOS tube, from Russia. The undistorted peaks at the bottom are only possible with a lot of emission of the tube. So it will saturate well. |

The same set up, nothing changed to the circuit or the scope settings. I only replaced the 6SN7 by a worn out tube from the 1950s. That (bad) tube tests only at 55% at a Hickok tester, and it is also totally unbalanced, this tube is junk, I just have it in my "bad tubes" box. But now look, how reasonable this circuit still works on it. Note the rounded edges of the triangle wave at the bottom, So yes, it does something "negative" to the circuit, but this tube is totally JUNK, and still this circuit works almost good in it. So I think we can say, this circuit works on any good tube. The picture quality is lower, but that is just caused by my Iphone camera. What you need to look at, is the measurement. The same set up, nothing changed to the circuit or the scope settings. I only replaced the 6SN7 by a worn out tube from the 1950s. That (bad) tube tests only at 55% at a Hickok tester, and it is also totally unbalanced, this tube is junk, I just have it in my "bad tubes" box. But now look, how reasonable this circuit still works on it. Note the rounded edges of the triangle wave at the bottom, So yes, it does something "negative" to the circuit, but this tube is totally JUNK, and still this circuit works almost good in it. So I think we can say, this circuit works on any good tube. The picture quality is lower, but that is just caused by my Iphone camera. What you need to look at, is the measurement. |

The End Stage is designed with a vintage working point of the 300B. As you may know, best sound and highest output power do not go together with tubes, and most specially with the 300B this is so. Amplifiers 'on steroids', designed for maximum output power, don't have the softness of a single ended triode. It is this disappointment which makes people use 2A3 tubes or even Type 45 tubes in the end. However, when a 300B is biased just moderately, a less dominant sound of this tube will develop. So the idea is here to get a nice and sweet sound in the first place. The result here, is an honest 7.1 Watt RMS , at the output of the transformer. This will need speakers with 91dB or better. |

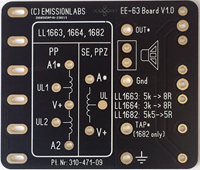

We recommend the use of PCB EE63 together with transformer LL1663. If using not solder wires, this fits nicely inside the LUNDAHL transformer covers too. Low Hum is achieved by DC heating of the 6SN7. Also good and correct wiring is needed to get the hum at or below 1mV, but this is possible with normal effort. See the additional notes at the power supply for this. |

|

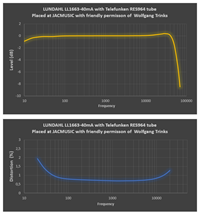

These curves were made by Wolfgang Trinks, using the Telefunken RES964 tube with Lundahl LL1663 and the Emissionlabs EE63 board. This tube RES964 has higher impedance as 300B, so it expected, frequency curves with 300B will be similar or better. It can be seen nicely, how well this transformer is designed. The amplitude chart is a dream. First note, this is the transformer measured, with a real tube, and not like the Japanese do, show the transformer driven with a zero ohms source. That would make the frequency chart artificially better. Just when you use a tube, you won't get those resuls. As you can see, LL1663 doesn't need this trick. Second note, RE964 is a 1925 Pentode, and some of the distortion results also from the tube itself. So what you see here, is tube and transformer distortion together. Yet, extremely low, 1.7% is by itself is much below the audible limit, and it only occurs in the very low end. |

The power supply uses also a Lundahl transformer, which is in it's base construction the same as a tone transformer, so it is not a low budget mains transformer. Advantages are extremely low hum, virtually no stray radiation, and very low heat loss in the transformer. For the rest we have to say this power supply has a special capability to reject a small DC component as sometimes present on the mains. Low cost mains transformers can be found for half the price of a Lundahl, but that would be saving money at the wrong end. 115V or 230V. I have shown a nice way how the transformer can be wired quickly for 115V or 230V by adding one or two bridges on a five pole solder strip, but of course you can hard wire it directly to the right mains voltage as well. Calibration of the amplifier, to the Mains voltage. This is always needed with any tube amplifier, just not everybody does so. The mains easily can be 5% up or down, or even more. By itself not a major problem, but tube heaters must be within 5%. In case of some doubt, it is better to over heat the tubes with a few(single) percent, than under heat. Best is however, do it correct. That will give best tube life, and it makes really a difference. That is why we use those series resistors in the tube heaters. The method is simply, first measure how far the mains is off. Suppose the mains voltage is 5% too high at the moment of calibration, in that case, the series resistors are adjusted such that the heaters are also 5% too high also. (So not compensate the mains error). Then, at some other day, the means is 3% too low perhaps, and the heaters will also be 3% too low also. As an average the tubes will be at 100%. As Power Supply choke, we use the Lundahl Dual Coil chokes here at the finest of their possibilities. it is called the Common Rejection Mode, so the choke is used as a 1:1 coupling element, short circuiting common mode signals, and bypassing differential mode signals. So it is signal filter and power supply choke at the same time. A miracle, nobody ever patented this. This is a choke with two 5Henry coils on one core. The outgoing DC current is passing through one coil of the choke, and the returning current through the other coil. The DC signal is serialized, but the AC stray field (called 'loss induction') is in anti phase for each coil which results in lowest hum possible. For calculations, this makes the choke act as 10Henry choke. For the tube rectifier an electrical symmetry point is created with two silicon diodes. I quote Per Lundahl's words here, that such a center tap will prevent mechanical hum, since it will per definition divide the transformer flux over two windings, at the moment the mains makes one half cycle. So it means if there is the positive cycle, the current flows still through both transformer halves still. Same for the negative cycle, but in the other direction of course. Still each cycle passes the rectifier tube the normal way. This will give a dead-silent operation of the main transformer. Try out the current path, and you will see! |

|

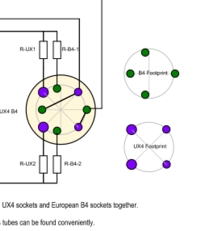

The rectifier tube used here is 5U4G mesh by Emission Labs, or with another socket you can use 5Z3 mesh from Emission Labs. It is very interesting to replace rectifiers by different types! Theoretically this makes no difference, but from blind hearing tests I once did with the Luxembourg Audio Note distributer, I changed my opinion. We did hearing test on the Audio Note, Mei Shu, 300B Amplifier, and we changed the rectifier 5U4G to 5U4GB. The difference was audible, neither tube sounder better than the other, but they do sound different. It was sure to use good, new rectifiers, that I brought myself and tested before. So since then, I speak against my engineering knowledge, and I say yes, rectifiers do have influence on the sound. So I always encourage people to try some different kind and difference brands. In this amplifier published here, you can use 5U4G, 5U4G, 5Z3, 5X4. These are all different tubes. 5U4GB (so with the suffix 'B') can withstand a higher first capacitor, which option we do not use here, so 5U4GB and 5U4 can simply be swapped. 5Z3 has a four pin UX4 base, same as 300B, but for the rest it is identical to 5U4G. The tube 5X4 has an octal base, a difference pin out as 5U4G, but for the rest it is identical. Even so, it is possible to wire an 8pin Octal socket such that you can fit in 5X4 or 5U4G. The Yamamoto Dual rectifier tube socket. The schematic we use here, generates the heater voltage here, with the series resistors in the rectifier tube heater. This allows a variety of rectifiers can be used by adapting the series resistors. Tubes can be used such as RGN2504, RG2004, AZ4, or AZ50. If you decide to go this way, note the supply winding of 6.6V unloaded, and has 0,1Ohms internal resistance, so you can make your calculations. Please check this drawing for how to use RGN2504 or RGN2004. We have stopped selling Yamamoto products, these sockets we has as long as stock lasts. |

Sound and electrical circuit: Please do not ask by an email description about sound, but a little but we can say. The driver stage is low noise schematic, and the heaters are all with DC. So when you build it nicely, and also use the hints that are in the schematics, this amplifier has almost inaudible noise or hum. The SE transformer by Lundahl is a very good one, and it is possible to get this amplifier fully flat in the audio range from 20Hz to 20kHz, so at zero loss. The pre amp and driver use 6SN7. This is the mother of all dual triodes. It was designed originally to have a tube like: 'What goes in, is what comes out". So no coloring of any kind. All you are listening to is the 300B and the SE transformer iron. (And yes, a transformer has sure it's own sound). |

The bias of the 300B. This is chosen relatively low at only 22 Watt. Yet this is a remarkable good working point, and a beautiful sounding 7 Watt will result from this. This lower power will take away the 'dominant' sound any 300B will have at higher dissipation, so sound at 22 Watt dissipation becomes a bit sweeter, more triode like. Option to use EML 300B-Mesh. Another advantage is the possibility to use EML 300B-Mesh here. At 22 Watt this is the perfect working point for this tube. The higher transparency of (real) mesh tubes will amaze you, provided you have high quality speakers which can reproduce this. |

Good functioning and power supply considerations: This schematic is free service only. Please understand, for legal reasons we must say, we do not guarantee the schematic. However, it has been build by several users, performance with the Lundahl SE and Mains transformer is very good. If there a problem when building it, please contact me by email, and I am sure we can solve this, as functioning of the schematic is very logical. What you do need to have a look at, is the values of some parts, which are responsible to create a certain voltage. These are:

Alternatively, use the newer Mundorf Tube Caps. These are bipolar electrolytics of a new technology, these behave like foil caps. They are only 2x larger than electrolytics, so much smaller than foil caps. They have amazing low internal resistance. So to say they combine the virtues of Electrolytics and foil caps This technology was introduced silently, but indeed this is new kind of capacitor, intended for power supplies. They do have a few uA leakage, which is irrelevant for a power supply, but they can not be used as coupling caps. They are available in very few values only, so these are good when you need basically just a high value. |

The Historical 'Kaneda' Circuit.The typical Lundahl 'CMR' topology for the choke is not new. The nice part if this is, it seems to isolate the rectifier part from the capacitor part better, because there is also a choke in the ground circuit. Yet, this can be wound on one core, and we loose no inductance, as long as the DC path of each choke is chosen correct. (Just use our schematic, and connect pins 1,3,4,6 of the choke this way). Note, this circuit is almost like choke loaded, as the first capacitors we choose very small. The Kaneda circuit does this as well, though you may see 'large' capacitors, but the Kaneda is a low voltage circuit. Yet, the idea can of course easily be adapted for high voltage too. For the choke used (T4) we definitely recommend a Lundhal, or any other type that can be used choke loaded. Being able to use it like that, is a quality element of any choke, and such chokes give no audible mechanical hum, also not after longer time. Low cost chokes will work initially, but choke loaded means higher mechanical (resonance) force on the windings, and if they becomes loosened over time, some mechanical noise will appear. This is no real defect, but it is annoying. Note, the choke is connected here in so called CMR configuration. You will find more information about this in the Lundahl Tech corner, here is a direct link, go here but remember to choose this chapter '1.1 Chokes for PS'. These are similar to the Kaneda circuit, but technically improved by Lundahl, and adapted for use with tubes. Take a closer look at this CMR circuit, and you will see there is no direct connection anymore from any part of the transformer or rectifier circuit to the power supply output, other than going via the choke. Knowing a choke cannot pass AC signal, this becomes a near-perfect l method to prevent power supply ground loops. It is of course only possible with dual chokes such as the Lundahl. |

PARTS LIST! Note = 1 x 300B-300B-MESH Amplifier Parts List |