Electron Engine ™

Printed Circuit Boards by Emissionlabs

The Raytheon Circuit

About burn in, little or no documentation exists. And yet, we all seem to know this is important. So, logically, this becomes the working field of "tube doctors", with movies on youtube, wearing a white doctor's coat, explaining the secrets, which only they seem to know about. Such silly situations result also from the tube manufacturers not being open about this, it was a little bit their own mistake. Yet I found interesting notes, in the Raytheon 5755 data sheet.

Now first, what is 5755? This is a tube with extreme stability, and low leakage, better specifications, low noise, long life, and a few more goodies. But do they come out of the box like that? No, even not in 1957 they didn't. (Print date of the 5755 data sheet). How come? Why didn't Raytheon burn in their tubes before sales? Well, they did! But the problem is always, burn in disappears after some time, and you just need to repeat it. They were aware of that of course. So what do they say, on page 2, note 2:

Tube data is only correct after 150 hours of burn in, using a typical circuit for that'.

So you see, from the Raytheon data 5755 sheet, burn in is not only warming up the heater 150 hours.

Raytheon says to use a typical circuit, but what does that mean?

If you know a little bit about circuits for small signal tubes, you will know they are typically auto bias. But Raytheon is more specific. They write, it may be auto bias or mixed bias. In other words, it may NOT be variable grid voltage. So yes, we see the makers of new made tube testers do so still, but myself I have no intention, trying to knowing it better than the old Raytheon engineers.

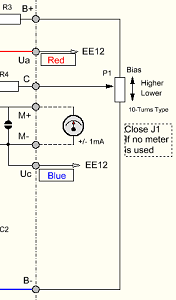

So we choose for mixed bias for the EE12 burn in boards. Like this we can still the change bias, and yet we can do as Raytheon writes.

The makers of this high quality tube write also: Data is not correct, unless burned in at least 150 hours. Wow... that is a very long time. It is almost one week. Imagine running 100 tubes for one week each in your normal tube tester. It would take you two years! We must be realistic about this, people that sell you burned in tubes, can NEVER do this with a normal tester. And no, I do no want to hear stories by some "specialists" that one hour is enough. If so, and Raytheon writes one week, Raytheon must have been mistaken, or the "specialists" are mistaken. But sure is, they can not be both right. I choose for Raytheon.

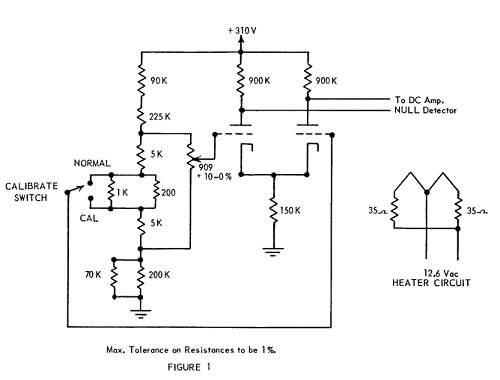

This is what they recommend as a test circuit. Do you see a grounded cathode, as done with all those modern testers? Well, I don't. Does that matter? Well, according to Raytheon, it does.

As you can see, this circuit has only an output. It has no input. So we see here, the small off-balance of the two grid voltages is independant of the supply voltage. The output is "zero" when the tube is balanced. Using a NULL detector is one way to find that out. Another way (as we use in the burn in device) is to connect both grids to the same (still adjustable) voltage, and use individual current measurinng of each tube.

One more difference with our circuit is, the 200k resistor (of the Raytheon circuit) we do not connect it to ground, but to a negative voltage. Like this, we can also use this circuit to check for good cut off.

One more difference with our circuit is, the 200k resistor (of the Raytheon circuit) we do not connect it to ground, but to a negative voltage. Like this, we can also use this circuit to check for good cut off.