Accuracy of tube testers Last Update: 29-Nov-2014 18:53 "fine scale" tricks (lies) The tube tester page started off as a short recommendation list, but grew a bit too large. So some parts (like the accuracy information) are now put on separate pages, like this one here. Click here, to return to the tube testers main page..

|

||||||||||||||||||||||

We can do an exercise with these identical thermometers at the left. In the middle is what we call the "system" it is the blue bar which moves. The numbers are the scale. So there is the system and the scale, and the scale reads the system. Now two things make the meter not ideal. First, the system has the specified tolerance, and second, the scale has an reading error. These meters are two out of the same production batch. As you can see it's pretty useless to show such fine stripes when the system accuracy is not very good anyway. Looking at the left scale, you can read 27.1 and the right scale 28.2. So a scale like 25 - 26 - 27 - 28 (etc.) would have been more like it. Then you would say: Left is 27 and Right is 28, and then actually both meters are considered "good" because one step in the last digit is allowed. (This is a general rule, and then we say the meters read the same, because the readings overlap). However, as in the picture, the left meter suggest 27.1 which at it's highest is 27.2. The right meter suggests 28.2 which at it's lowest is 28.1, and that proves the very fine hair stripes out more precision in the scale, as the system has. Now this is not illegal, but if fools the unexperienced user. Even worse if there is not precision indication on the meter, you may assume the finest scale stripe is valid. In that case, there is no overlap and the only conclusion is: One of the two meters is defective. As long as you have only one meter, you feel happy with the "precision". Another way to make this clear, is the following, suppose both meters had no finer divisions, so only 10 - 20 - 30 etc. Then each meter would read "just below 30". Which is true for both of them. And then again both are no defective. So if the accuracy of the system (the blue bar) is low, you cannot make it better with very fine divisions, and the instrument maker should not do so. This is the elementary way of true accuracy interpretation in engineering. So a correct meter, can have low accuracy, but it should present you a scale with without fine divisions and then it's ok. This actually has become a general disease with all tube testers, and make good note they are usually fooling you. So I put this issue up front here. So no extremely fine scale stripes should be penciled on a 15% accordance tester. Excuse me, but most Hickoks are a negative example for that. |

||||||||||||||||||||||

|

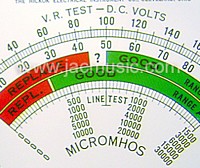

Meters like the later Hickoks use ultra thin hair stripes with a much finer resolution that the whole tester can ever have. The meter shown here is not even so bad, there are much worse examples. You read something "very" precise from a fine scale, dividing the 1500 Mmho range in steps of 25Mmho. (this is so crazy.... 25Mmho on a 5% error tester). So the difference is indicated between 1475 and 1500 Mmho. This can never be so because the whole tester had 5% deviation at it's best when it was new. (At this scale 5% is 75 Mmho). Well and some are even 15% and they use the same meter. Did they know this at Hickok? Well of course they did! The older Hickoks like I-177 do not suggest a higher accuracy as it actually has. You can read the Gm scale only very roughly, which more represents what the tester is actually doing. And nooo... If you think now the I-177 is imprecise, you missed the point. It has the same precision as any other tester. Just be aware that the later models with the very fine hair stripes are sometimes just 15% precision testers, and you can't change that by adding more fine hair stripes suggesting 2% resolution. |

|||||||||||||||||||||

|

The early AVO Mk1 has the "very fine scale" trick also, they really were overdoing that. With the later models Mk2...4, CT160, the designers at AVO have come with their feet back on the ground. With CT160 which is the most precise of all AVO's, the lower scale has numbers like 20-40-60-80-100 and divides the range from 80....100 only with five stripes. This is true honesty, because indeed by no means the whole tester can't do any better than that. The mega Ohm scale jumps from 10Meg to 25Meg. It just tells you in between you can estimate the number yourself, but the tester cannot, which is true. All it will tell you the resistance is in between 10 and 25 Megs, and if closer to the one or to the other number. Keep in mind measuring 25 Mega Ohms is not easy without electronics. However, at lower resistance it gets better, being able to measure with 50x more accuracy (200k) . Mmm still a lot of deviation. Is that meter not good? Oh yes it is! It tells the truth about the measurement. So when I measure 5250 Mmho with accuracy of 500Mmho, I believe this. I love my CT160. When I measure 5250 Mmho in a Hickok with a suggested meter precision of 25Mmho, that 25Mmho resolution is bullsh.... I don't believe it at all. I never use a Hickok for precision measurements, but it must be said the red-green scale works perfect, perhaps the best of all testers. When talking about accuracy, the red/green scale had only "red", "green" and "white" in-between. Well fair enough, and that's what you're getting. |

|||||||||||||||||||||

|

Very accurate is also the Funke W19. Very much information about it you will find on the main, including a full restoration report, and meter calibration. Just as a fun project, I re-build this one to the best accuracy I could get. The little digital meter you see here, is just for the pictures, but it happens to be a good one. Actual restoration has been done with a new Agilent digital meter, which is not on the picture. Very well done with the Funke is the voltmeter option, since that very quickly tells you something about the panel meter (after all those years). Note old panel meters often show a few % less, due to the magnet loosing it's magnetization. With all old tube testers, you have to begin with calibrating the meter, and get readings + impedance back to what it should be. This is a rock-solid, feet on the ground, correct and honest tester. Well worth the +1000 Euro price they go for. | |||||||||||||||||||||

|

For our German readers, or those who want to give it a try. The FUNKE W18 manual gives really good information about tube testing in general. (Ab Funke seite 11 lesen, =Pdf Seite 8) |

|||||||||||||||||||||

Tester accuracy and errors

"When you make a measurement, you must know the uncertainty. Otherwise it is meaningless"

When you intend to work on your tube tester, always see those as instruments. So if you intend to improve the accuracy, don't expect to get any wiser from just opening it up with a multi meter in your hand, and no experience and no manual. I fully understand, and I had this little bit naive idea myself too, when opening my first tube tester. Inside was no potentiometer in there, called "accuracy", and no test points to connect my multi meter to. Reality is, the easiest to buy tube testers, are the hardest to repair, and the most often broken. There are many problems and issues with tube testers. Most tube testers works like this: It does some test on the tube in some way. Then it refers this to something in some way, which is then the "result" presented to you. Take the previous sentence and replace the word "some" by unknown. Then the following text makes the situation more clear to you: A tubes tester does a test on the tube in an unknown way. Then it refers this in unknown way to an unknown reference, which is then the "result" presented to you. You still like it? Add to this, many testers are good / bad kind of testers, but let you believe it's an instrument. Also some testers have no problem telling you "50mA" on the scale, while in reality there is only 25mA. (and that's the normal way... no defect, with many AVO's). The testers with all kind of "patents pending" are the ones for a guaranteed head ache. Patented means they measure in a way no normal person ever though of. And you are opening up the tester in question or broken condition, and think you can fix it. Besides, for me testing a tube the normal way (not patented way) is the best way, because that you will at least be able to understand, and there is nothing wrong with doing things the normal way. To give you an example, with an AVO Mk2....Mk4 you are supposed to measure the grid and plate voltage (which is in this tester half wave rectified AC voltage) with an AVO Type 8 multi meter. The reading on that meter involves the load that meter gives on the circuit. So take any other meter, and you get another result. The AVO Mk8 multi meter is one of the finest multi meters ever made. If you take an digital meter, you only can do when it's true RMS, and you need to simulate the AVO meter load which is 20.000 Ohms per Volt, but then you're ok. The main thing to realize is, accuracy with a tube tester comes from all components to be good. I cannot repeat that often enough. You need to systematically check your tester. This means you must check all parts, all voltages one by one. Really just that way, and there is no other way for an old and dirty tester. So you begin with tube sockets deck. It is enough when one socket is leaky at one contact only, and you can forget about the rest, since they are all in parallel. You need to disconnect the socket deck from the rest of the tester, and then you need minimum 20 Meg ohm from each contact to ground, and to each other contact. Well, and after that you take the next part of the circuit, the shorts-and-leakage test. You must test basically everything. Also the transformer can have one bad winding for one of the voltages. Some idiot may have run a shorted tube on the tester for 30 minutes. Even if that was 40 years ago, the defect has not self-repaired since. Then the needle instrument, it is often unlinear. Sometimes because of lost some magnetism, more often because of coil deformation due to operator errors. That can be corrected if you have tiny fingers and fine tools, and have a few useless panel meters to practice on. You can have a problem with the transformer you didn't notice, and all kinds of nasty and hard to find things are in fact NORMAL. Have you ever heard that tube testers are made for 110V, and now we have 115V? (or 220V vs. 230V). If you think that doesn't matter, then take a Variac, and try it. I can save you the work: It does matter. Then, many build in problems, most of the time were not found be the people who owned it before you. How could the poor guy know. So if the 6.3Volt winding for the filaments has a partial short circuit, it will give 6.1Volts only, someone before you just boosted up the transconductance reading a little bit, change a resistor here and there, and once the meter is there were it should be, with most of the tubes, there is your good old "calibrated" tester. And now you have it on your bench, and you see it measures good for one tube type, and not good for another. You would like to fix it, and have no idea where to begin, and from looking at the inside wiring you won't get any wiser. Add to this the leaking switches, fungus wiring, leaking capacitors, and off value resistors. To be honest, with almost all testers I found, this is the normal situation. These nasty things I write here, to bring you back to earth! I really like to restore a tube tester from the beginning. Not fun is only try to fix that particular part that causes some kind of a problem. If.... your tester is older, here is an important thing to know. Many testers can be bought in newer or older versions. In MOST cases the older versions can test the more older kind of tubes, that today are HiFi tubes. For instance the Neuberger RPG370 has all the nice sockets you need, for PX4, and AD1, and 2A3, etc. The newer tester RP375 has only modern sockets, and you can see from the choice of sockets, they didn't want to deal with old crappy tubes. So it can't even test a 2A3. However, the older RPG370 is indeed a LOT older, and it has all kind of problems that come with age. Such as the capacitors, and other things, whereas an RPG375 you can open up and see shiny new materials that are all good. Same issues with the Hickoks. And AVO too. So the older Mk2, is a wonderful tester, it allows better settings for 300B and 2A3 that you can't do with a Mk4. However, a Mk2 is often in very poor condition, and it needs a full check up, and a Mk4 may be in a condition where you can trust must of the inside guts still. So this is kind of a dilemma. However, an "original" condition RGP370 will keep you busy for a while restoring it. I once had an original condition RPG375 that needed only cleaning of the potentiometers, and that was it. Testers from the 1970's can be such that you can use them mostly as they are. Testers from the 1940...1960's have inside components of too old technology. Many C's and R's are bad. Then, in the end, all I can say, you need some reference tubes, of which the values are specified for 100% sure. Ask your potential repair man if he uses such tubes. When he can fix you tester in a jiffy, because he has so and so many years experience, then surprise him with a www.jacmusic.com reference tube, and ask him kindly to measure it exactly for you, so you can verify your tester. And don't let him know, you have all test data anyway. If he can't tell you the right value of those tubes, he has not even calibrated his own testers. Folks, I have seen so many tube testers before, and it is the standard procedure, that the owner thinks he is the lucky guy with the perfect tester. He is sure what he is testing is right. However, if he would have had two tube testers, he would probably trust neither of them, since most testers have different test results with the same tubes. The crown of this story is, that buying a calibrated tube (oh yes we sell those useless things) is still regarded a waist of money by many. Here comes the crazy part, it really happens. Sometimes a customer buys a calibration tube set, and comes back after a while with a complaint: The values written on the tubes is not the same as read by his tube tester. And the only explanation he can think of, there is something wrong with the calibration tubes, because the tester was "believed" to be good, because it was always good. Well I failed to understand this, but I can live with it.

TUBE TESTER CALIBRATION TUBES. Order Nr: 624-014-55. See price list, appr. line 690 RECOMMENDED TESTERS: Recommended testers look for instance like this.

Not Recommended testers look like this. Avoid like monkey plague. You can recognize them by the characteristic row of small switches.

|

||||||||||||||||||||||