AVO Tube tester MK3 and Mk4

Some Projects

|

See price list for pricing. Order Nr: 624-030-59 |

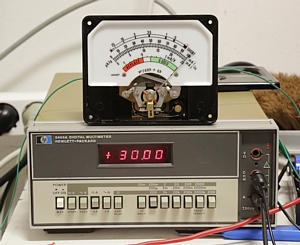

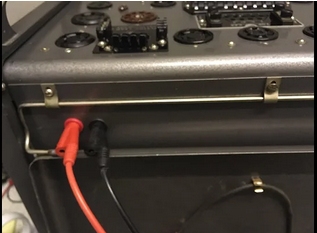

OUTPUT FOR DIGITAL METER.The original panel meter stays normally functional. At the back of the tester come two banana connectors, for any digital voltmeter you have. Only thing, it should not be a true RMS meter, but a low cost averaging type. The modification we do it in the original style of the tester. So cables are added to the cable tree, etc. We do it such that you hardly will see it. You need to send in the tester for this. Sorry, but customs office makes too much trouble, we do not take shipments from outside Europe. |

|

Project 2Just checking up this AVO turned into a full restoration. |

|

Curve Tracing with an AVOIt requires an oscilloscope with an X-Y deflection. |

|

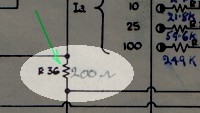

The very remarkable Ohms Meter of the AVO tube testers. |

|

Read about an error all AVO have

Perhaps we say it was not an error, but they found no better way. |

|

Meter availabilityOriginal replacement meters are impossible to get. What you see on Ebay reflects that a tester without meter is worth very little. You can't buy the meters, and who knows what's wrong with a tester that someone removed the meter from. I have only once seen once an NOS meter on Ebay, ever since 20 years, and it went for appr 700 Euro. So chances you find a new meter of Ebay, is virtually zero. Yet the price of 700 Euro was justified if somebody puts it in his tester, and sold the bad meter on Ebay. There is always somebody thinks he can repair it. Picture1 - Picture2 - Picture3 - Picture4 |

|

Meter RepairThis is possible in most of the cases. The only thing that cannot be repaired is a dead coil, though this may only appear so, and you have only a bad contact somewhere. A repair is always a complete overhaul at a flat rate. I cannot just repair a loose glass, and leave all the dirt inside. Also, most meters I had here, have seen some repairs already, and some kind of unsolved issues, or damage by actions intended as repairs. So a complete overhaul is always needed anyway. A Simple way to test the meter of your tester |

|

REPLICA METERSSorry, we do not offer those any more, die to lack of interest. It is strange, because for many, this was the only option to repair a tester with a missing meter. |

| Some raw information about a sticky roller switch | |

Screws and the sense or nonsense of the INCH vs METRIC mess.

So in many cases you have quite a good Mk4, but it has rusty screws. These have an obsolete British thread. In history there was some sort of a war going on, where all countries invented their own thread. INCH vs METRIC.With standardization, it doesn't matter if you do it like this, OR like that. There is some pro and contra in all. But you get the ultimate mess, when you do it like this AND like that. In the USA they are still trying to prevent metric thread. I give them little chances, metric is too logical to ignore. On the other hand, there is a surprising advantage in the Inch system, because they keep on dividing dimensions by two. This means you never have odd numbers. Let me explain. Suppose you start with one Inch. Then you have 1/2 Inch, 1/4, 1/8, and 1/16, etc. Whereas 1/16 is 1.56mm and thinner screws are hardly ever needed. 1 Inch is a huge bolt, and 1/2 Inch is already a very fat one. So in between 1/2 Inch and 1/16, is where the most use screws are found. Dividing that in steps of 1/16 will give: 8/16, 7/16, 5/16, 4/16, 3/16, 2/16 and 1/16, and not even all of them are needed. This is a great advantage I see here. On the other hand, same as it is easier to express engineering items in German than in English (it really is) it is easier to express dimensions in millimeter. So resistance against metric system will be there for a long time, and in the end, they will probably give it up. And this is what I say, when you give it up anyway, it's better to do it now. However, in the Inch System, they did not standardize the thread pitch originally in such a way that it was final. (So how many Threads Per Inch, called TPI). When equipment is older, you need to research a bit on that. For the Mk4, the front, back, and side panels are so called British B4A thread. This was a 'fine' thread, once upon a time in use for clocks. Well and they used that for the Mk4. It's quite similar to American 6/40 thread, but B4 has 38 TPI (threads per inch) and 6/4 has 40TPI. Now 38TPI and 40TPI is a large difference when the screws are very long, but a small difference when the nuts are thin. If thin, you hardly notice. The screw goes in initially normal, and when going through becomes just a little bit heavier, but not much. If the screw goes into some threaded chassis part however, it will not work. That is because it 1/2 Inch you miss already one thread. (So 6/40 vs 6/38 is tho threads difference over 1 Inch) Meaning a 6/40 screw you may be able to get it inside a 6/38 threaded hole for a few rotations, but then it gets heavier, and gets stuck. For the back panel and front panel you can use the easier to buy USA fine thread 6/40, though it's also a vintage product. For the side panels you can only use B4 thread, because the screws go in quite deep. For the side panels, you can overcome that by cut off the screw at appr 5mm. (First put a 6/40 nut on it, then cut it off. If you don't have a 6/40 nut, you can borrow a 6/38 nut from the inside somewhere). The front plate screws are called ''slotted raised countersunk B4 machine screws''. Wow. You can google for that. Some UK companies still offer those screws for acceptable prices, like 1$ each. Same as what vintage 6/40 screws go for, at Ebay.

| |

|

Some unofficial test points for the Mk4 only |

|---|---|

The AVO Mk4 originally had a plastic dust cover with it, and it's an extremely good thing when that is still with it. Sure such an AVO was not kicked around, because the plastic tears easily. So when it's nice condition, that's a perfect sign. Not just the cover is worth 40 Euro, but I find the dust cover is a very good protection against oxide of all metal parts, and against sun bleaching of the adjustment wheels. Also the paint is a cleaner color then, there is not this brownish faint, and the slot for the tube book is cleaner also.

The AVO Mk4 originally had a plastic dust cover with it, and it's an extremely good thing when that is still with it. Sure such an AVO was not kicked around, because the plastic tears easily. So when it's nice condition, that's a perfect sign. Not just the cover is worth 40 Euro, but I find the dust cover is a very good protection against oxide of all metal parts, and against sun bleaching of the adjustment wheels. Also the paint is a cleaner color then, there is not this brownish faint, and the slot for the tube book is cleaner also.  This picture are new made screws I bought from a German company: www.astro-electronic.de. They are 6/40, so they have not exactly the same thread (which is 6/38) , but after a few times in and out, they are just right, because they should not run too smooth anyway. I used them for the side panels, behind which is the fuse and calibration. Just for fun because they looked so nice. However, they are 6 Euro each, incl. local shipment.

This picture are new made screws I bought from a German company: www.astro-electronic.de. They are 6/40, so they have not exactly the same thread (which is 6/38) , but after a few times in and out, they are just right, because they should not run too smooth anyway. I used them for the side panels, behind which is the fuse and calibration. Just for fun because they looked so nice. However, they are 6 Euro each, incl. local shipment.