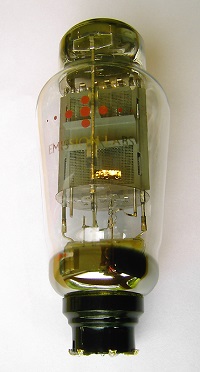

Portrait of a tube

AD1

Little is officially known about the AD1, but many collectors regard it the queen of the European DHT triodes. Not without reason, Japanese tube lovers have started collecting this tube already in the 1980's. AD1 was intended for large radios and cinema amplifiers. Today you can buy those AD1 radios on Ebay, but the AD1 tube is always missing. So you would need to spend something for a used AD1 which at least works in the radio. Yet such radios are really worth the interest, as these use always highest technology. Also, there were none-FM Radios, which generally have better receiving quality than FM radios, where AM receiving was only a by-product. Very high end AM radios had sometimes tone control, by removing higher frequency disturbances by shifting the high end of the bandwidth filter a few hundred Hertz down. Like this creating a very sharp cut off, much better as analog tone control can ever do. Things like that you can find in specific top class AM-only radios. AD1 was also used in professional music amplifiers for dancing rooms or cinema.

AD1 was introduced just before the second world war, und during the war 'big' radios and dancing rooms were no item any more. Already during the war, military small pentodes were made. Then after the war, the high need for new made, lower cost radios ended the production of the AD1, before it had really started. The market required high quantities of small size, low cost tubes.

AD1 was introduced just before the second world war, und during the war 'big' radios and dancing rooms were no item any more. Already during the war, military small pentodes were made. Then after the war, the high need for new made, lower cost radios ended the production of the AD1, before it had really started. The market required high quantities of small size, low cost tubes.

Quantity. I only know the exact quantity of Telefunken AD1 ever made. Production was started in 1935 in Berlin, and ended in 1945 with a total quantity made of 265.000 pcs. So this is Telefunken only. The may seem like a low quantity, but we must see this was before mass production of TVs. A very successful TV tube, like PCF82 or PCL82, would perhaps be made in a total quantity of appr. 100 Million or more, for all manufacturers together, ever since. The killing factor for AD1 was really WW2, and the fact that after WW2, such tubes were not needed any more. The tube RE134, which was also a radio loudspeaker tube. This much smaller predecessor, went through it's intended life cycle, and was build in a total of 4.2 Million pieces, until it was followed up by AD1. Most likely for AD1 something similar was planned, but it just did not come that way, due to the war.

The AD1 socket, type P8, or Au8, got obsolete, because it can only be hand connected to 'wired' stem tubes, and not to the after-war tubes which typically had their pins directly through the glass.

The original base looks a bit strange, but it has an interesting proüerty. It pulls the tube inside the socket, and it closes the chassis part with a rim, like the a lid on a pan. In the picture you can see this rim in the middle of the socket. So no dust can get inside the amplifier. You need no tube retainers, the tube pins are self cleaning, and the chassis part can be accessed for cleaning with a cloth. If you ever tried to clean an octal socket with a dirty contact you know what I mean. It is a true high-end socket, and several military sockets were inspired on this technology later. Yet there is also interest in UX4 bases, so we offer a UX4 base as well, just to serve the need.

Alesa Vaic, you can call him the first pioneer of building retro tubes. He was the first, and he made AD1 too, some time after we joined up in 1998. I knew him personally very well, and we had many long conversations about things we could do, or should not do. He was already collecting radio tubes in the 1980's and he always pointed out to me, the superior sound of 4Volt Directly Heated tubes. When designing a Directly Heated tube, there is not much choice for the cathode wires one can take. You can try to make the wires thinner or thicker, longer, or roll them flat, but whatever you do, you will see it is usually not an improvement. Those old companies of course did the same, and what they came up with, was no coincidence. In the end, what sounds best, was 4V tubes, with medium size anodes, like RE604. PX4, or AD1. I was involved in the hearing tests, we did with a friend of mine, in Konstanz, who had a pair of the original "Corona" plasma tweeters, build by the inventor himself, Otto Braun, with larger diameter of the flame plasma. I did not like the smell of the flame very much, but sound was the best I ever heard. We choose for the mesh version, instead of solid plate, because of the better sound.

Efficiency of heater was an important item when AD1 was created by Telefunken, because typically DHT were heated with batteries. Another reason how 4Volt tube heaters were born, was this one: First electric lamps for bicycles were 4V types, which is logical, because the tungsten wire of such lamps is short and thick, giving best reliability, and it needs only two cells instead if 3, as with 6V. Whereas one cell, with 2V would result in twice the current, and both lamps and batteries would not be the best. Reasoning for radio "lamps" with Tungsten wire, was not any different. Besides the higher DC voltage gradient which 6Volt would imply, makes it harder to use such tubes at very low bias voltage, as was needed, due to low emission. So, 4V was the best for the first high volume radio lamps, like the Marconi R-type. It was 4V, 0.75A, and very good heater batteries were available. The Ever Ready Company had even a so called "Dry Cell" in the program delivering an amazing 600 Ampere-hours at 4 Volt. Able to operate the heaters of 4-tube radio for 200 hours. This battery was activated by filling it with clean water, there were dried chemicals inside, which would activate and make the battery ready to use. The dry storage time was very long. In those decades, 4V batteries for radios were normal, and easy to get. Yet, the tubes had to be low current, as best as possible. Here is where the AD1 engineers of Telefunken did a great job. Though we must say, it was on cost of maximum achievable lifetime. The TFK AD1, as we know had no lifetime issue. So it was not impossible, but I think they doted the cathodes also slightly radio active. We would not dream of that today, of course. So what did they do.... The cathode wires were initially not Barium Oxide coated. I have a 1930's RE604 lab model here, with the pill not activated. They used n nickel alloy. The Barium depot is inside a 'pill' in a cavity in the middle of the anode, at the inside. You can also see from that cavity from the outside. When the tube is ready build, the Barium pill gets evaporated by heat, and Barium is spread all over the tube, also to the heater wire. Then, by electric methods, combines with heat, the residue gets removed, and a thin layers stays on the heater. Also Barium as we know is a good gettering material. All in all, a clever, but very difficult process. This results in remarkable heater efficiency, but on the sacrifice of having not much Barium on the cathode. Yet they did it, don't ask me how, lifetime was good, and no electrode leakage. The Philips and Tungsram types are not fully free of electrode leakage problems. Valvo are very good also.

Heaters at AVVT and later at EML. The original Telefunken AD1 had 0,9A and a condensed Barium plating. The later AVVT, we developed as classical Oxide Cathode AD1, it was in small quantity. This first ever re build AD1, had heater current of 1.1 Ampere. Lifetime of this tube was unfortunately not quite as we hoped. But they were reliable and technically good. Later at EML, we re designed the AD1, for optimized lifetime, as lifetime is a company principle. The choice for 1.1A, at AVVT, was to stay closest to 0,9A as original, but this was an unlucky choice for the lifetime. Since at EML it was clear, we were not compatible with Telefunken's 0.9A anyway, we decided, to go for 1.5A and achieve maximum lifetime this way. The heat of 9 Watt (heater power) would also deal better with challenges resulting from mesh anodes. So we could made AD1 a mesh tube from the beginning.

How to use AD1. Well there are several old schematics around, and new made schematics too. But basically there are two things possible, if you look for inspiration. First, AD1 at voltages same as 2A3, will fit into most of the those schematics directly, by adapting the heater to 4V. The 2A3 (historic RCA type) however has a small and fragile tube stem, and somewhat small construction inside. AD1 has more spacing inside. That, and the somewhat wider tube base, allows higher voltage working points of AD1. So this comes in addition to the medium voltage working points, same as 2A3 which are also possible. The higher voltage working points will shift AD1 in another operating area, with higher output power, caused by better efficiency. This is quite another use, and (the same!) tube becomes medium impedance, at better efficiency, higher output power, and less distortion. So this is only possible with AD1, and not with 2A3. The overlap is in the advantage of AD1. These working points, so 2A3 mode, and AD1 mode, are given in the EML AD1 data sheet.

Estimated Lifetime of AD1. Telefunken and Valvo 1500-3000 hours. Tungsram, Philips, AVVT: 1000..2000 hours. EML up to 40.000 hours.

External Link to 4tubes.com for schematics and documents. Click there on schematics, and browse to AD1, or check at datasheets, literature or other places for AD1.