Author: Jac van de Walle

Description

826 is a transmitter tube for maximum 250mHz. Like most transmitter tubes, it is a bright emitter tube, so the glow picture is beautiful. Yet, UNLIKE most transmitter tubes, it can also work at just a few hundred Volts. This is done by positive grid voltage, as a fully normal and intended way to operate this tube. What this means, I will explain a little bit here.

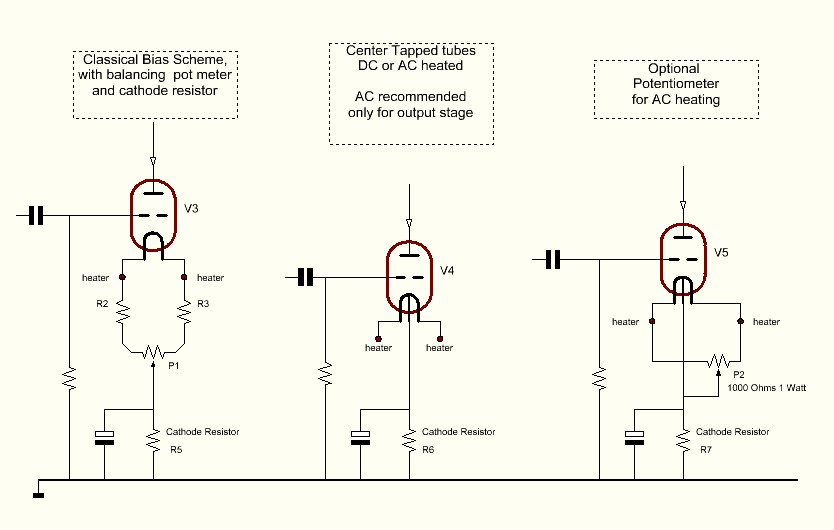

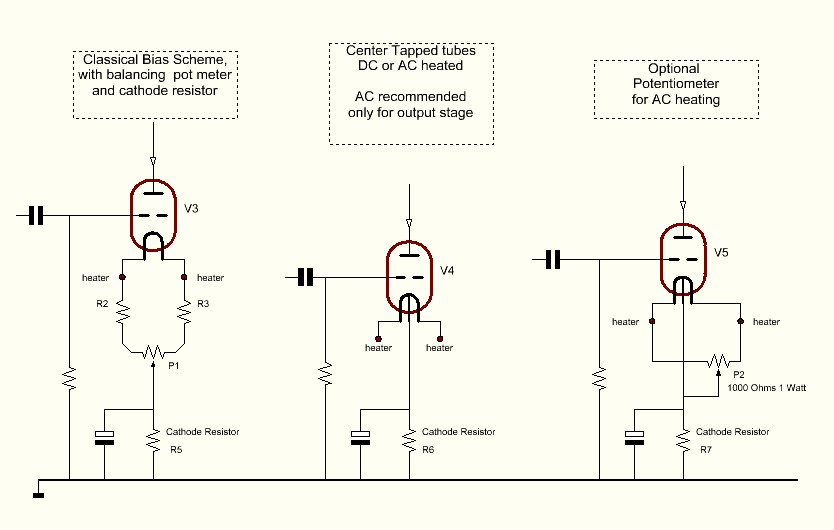

My first experience with the 826, was a theoretical one only. It is one of the very few DHT (Directly Heated Tubes) with a center tap on the cathode filament. Inspired on this tube, we build the V4 Series (center tapped heater tubes) at Emission Labs, but it was without having ever touched an 826.

Center Tapped Heater with Emission Labs V4 Series tubes.

This article is about 826 though. At higher frequencies, simple things like a short wire piece, have already enough inductance to cause a lot of phase shift, and in many cases, the high frequency limit of the tubes is are limited by the way the tube system is connected, and the way the tube is wired inside the glass. As we all know, two devices if put in parallel, have half the inductance and twice the capacitance. In case of the 826, the grid is connected with two wires, which are far away from each other. Capacitance is mainly coming from the grid itself, not from the wires. But with two wires in parallel, inductance is now only half. They do the same with the anode. The filament is also in the signal path. So how to do the same with the filament. The filament is not only connected with wires, it is also a wire by itself. So connecting the ends with double wires many not so much be the big help. Besides, there are only three contacts available on the Septar (7Pin) socket. So they tap the heater wire in the middle, and the electrical signal can be take right out if this point. Without having to go in detail too much, you can imagine, there are ways to connect the filament such that inductance is only half.

Gassy tubes.

Some people write this is a notorious problem with 826, and from the two pieces KEN-RAD I have, one was gassy indeed. After taking it apart it soon appeared somebody totally burned down the inside. . So gassy yes, but not by itself.

So how "terrible" this problem is with NOS tubes, I cannot sa from just two tubes. But sure seems this abuse ended up in a gassy tube.

The other good tube was testing as a perfect copy of the datasheet.

So if you want to do a quick test for the 826 being gassy, and you don't have a high voltage tube tester, I can say this: The filament glow color should be normal, the current should not be higher as normal.

The bad tube

After opening it up, it became pretty obvious somebody before, overheated it like crazy. To me it seemed also the glass was pre damaged from this, and it cracked to easily.

The gassy tube was first investigated better. First thing I noticed, was the filament glowed only orange instead of yellow. Moreover, the current draw was 4.8 Amps instead of 4 Amps. So there is a air inside, enough to cool down the filament. The lower temperature resulting from that caused the darker glow, and lower resistance of the wire too because of lower temperature. So current is higher. The tube was totally dead on the tester.

But now for a mysterious observation: Only after 20 seconds, the anode coating became loose. The black powder fell off, and it was everywhere inside the tube. I have no idea why that happened, and this was unlogical for just a gassy tube. Definitely the anode was not very hot, because there is no anode current possible anymore. |

|

Glass breakage

After the anode powder was crumbling off, I tapped gently with tube glass on the bench. This seems quite a thick layer. Then, to my surprise, the glass broke unexpected, without violence. It is obvious from the socket, this is part is hard glass, and likely also the envelope, to my opinion this glass is much too thin. So be aware, the glass may breaks before you realize it, this not fully without risk in a working amplifier. This may have been caused by the previous overheating, or the glass is just like that always. |

|

So next thing I tried, was breaking off the glass further. So I tapped a little but on the glass, expecting more pieces to break off. But nothing broke off. Instead of that, the complete anode just fell off in once piece. Looking at how it is mounted, that should not be possible. The welds obviously were burned too. So they got brittle. |

|

This is a detail from the anode inside. Now, such shade patters are nothing very unusual with used tubes, and such that are at the end of life. This material material from the cathode, which somehow finds it's way there. I have seen it with 6SN7 and 300B, the same. However, here, it is more than a shade pattern, it is really a fat layer of dust and particles. Very strange for this to move through vacuum. But as you can see, that is the case. |

|

This is the filament with the grid around it. Now it becomes mysterious again, The is a Thoriated Tungsten tube, and I always thought these had no coating other than a very thin tungsten-carbide surface. Well, not this one. In the middle the wire is much thinner, and not black anymore. You can see some stuff had chipped off, and really very much of it. Long crystals are growing too. Click on the second picture, and you will see it in detail. At the ends of the wire, the coating has not come off, and it is relatively thick there, and black. Obviously, the center must have been like that too, when the tube was still good.

Then, where the heater wire comes out of the grid, they applied also no coating, and it becomes thinner again, and from there the wire is connected to the terminals of the tube stem.

So far for this "NOS" tube I bought. I do need to credit the seller, I did not have to pay it. |

The good tube

That is another story. This tube works perfect, and it is like a copy of the datasheet. With DC heating, and my anode voltage, the datasheet said: +37V grid voltage to get 100mA. And that was exactly correct. |

|

This is the tube with only the filament on. It is surprising how hot the tube pins get from this, specially the center pin When mounting the tube, it is a good idea to solder small coolers perhaps on the tube socket from the inside. If you do, it is very important to paint those black. If left shiny copper color, cooling effect is smaller. Also very thick wiring will help to remove the heat from the tube socket. Since the center tap will probably be grounded in the schematic, it seems a good idea to to this with a very thick copper wire, or twist some wires in parallel, so to get the heat away from the socket. |

|

This is the tube with 450V anode voltage and 125mA current. So not even full power. Often, cameras do not display glow temperature right. This so for the top part, where the filament appears to glow white. It is yellow-orange instead. The light at the anode and at the tube bottom is displayed correct. |

|

|

How to use this tube.

This an unusual tube. Though it does have a very small range for negative grid voltage, it is clearly intended for positive grid voltage. Though DC current is very large then, like 20mA is possible.

Tube characteristic.

Though the 826 tubes does have a very small range for negative grid voltage, it is clearly intended for positive grid voltage. DC current is very large then, like 20mA grid current is possible. Normally a tube is biased with negative grid voltage. However, when attempting to use the tube at relatively low anode voltage, this will require such a grid voltage which can drive the signal peaks into positive grid voltage. This gives extreme distortion in no-feedback amplifiers, because the characteristics for positive grid voltage are totally another as for negative grid voltage. With the 826 however, even biasing the tube requires a grid voltage of around +30V, and so the whole signal sweep can be done with positive grid voltage. This is something fully different as what most people are used to. Moreover the load impedance is relatively low, so the 826 doesn't just need an input voltage, it needs also some input POWER. As a driver, a powerful, low impedance tube is needed.

WILL BE CONTINUED