Heater Voltage of tubes

It is such a miracle, that tubes work so well. That is because everything inside is a difficult compromise, between parameters, performance, cost and reliability.

The main parameters (most important first) to make the heater and cathode last longer are:

- The heater voltage

- Tolerance of heater voltage

- Slowly switch the heater off.

- Slowly switch the heater on.

Have you ever cooled down a glass item, or pottery too fast? So what happened, it cracked. Have you ever warmed it up too fast? Unless you do crazy things, that doesn't give a crack. So we learned something important here before:

Cracks are caused by fast cooling down, while fast warming up is less of a problem.

Metals are no exception with crack building. Do not think of metals as something made of one piece. Though it looks like one piece,all metals are crystals, and these can break off.

If you poke into a solder joint, while it cools down, you can l see the crystallized surface. These are real crystals. Even with a smooth or polished metal surface, it is completely formed of crystals. With metals, the main factor, which determinates the strength (or softness) is the way it was cooled down after melting. This determines the crystal structure. Also metals recrystallize continuously, even when cold. The crystals, if under mechanical tension, begin to build future cracks. This process is accelerated by temperature cycling and humidity. So to prevent breakage of heater wires, mainly cool them down slowly.

Warm them up slowly is not a great help, but it may cause cathode stripping. Slow heating up is EXTEMELYE damaging, if at that moment already plate current is flowing through the tube. This causes emission loss. I agree, these electronic modules look nice, and interesting too, but some of them are tube destructors. If a slow heat up electronic module is used, you ALWAYS have to switch off the plate current, during the heat up time. If you want to build something useful, better build a "slow cool down" module. But keep in mind, these also need to have the plate current switched off first.

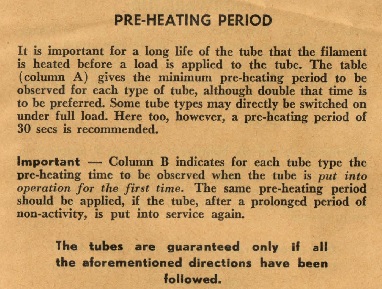

This is explained here is six languages by Philips, for their rectifier tubes, but no power tube is excluded from this.

Information Sources

|

If you think it is possible, the manufacturers of the tubes know what they are talking about, follow their advice. If you think manufacturers don't know much abut tubes, and good information comes only from anonymous experts on the tube forums... , well then you know who to ask. |

|

Glass Audio, or similar, but old issues are hard to find. Also most old American magazine from 1925...1965. Just dig into those old articles, and you will be amazed about the 10.000's of top class articles you can find in those. Go to 4tubes.com under literature and find some of the best magazines and articles from the 1930's.. |

|

Good DIY builders are to my opinion the most reliable. This is just my personal experience. |

Amplifier Manufacturers |

Some are excellent. Most are hard learners, and never admit a mistake. Like when the tube data sheet writes maximum 33uF Capacitor on 5U4G, some fools take a larger value, and say the data sheet is mistaken. Then if the tube gets broken, the problem is the tubes they say, because it never went wrong before since 1965. |

|

Please don't bother me with this. Such modules are a source of problems almost by definition. These solve artificial problems, like create a slow start, which by itself is a stupidity, if the tube is under anode voltage. If you want to build something clever, auto bias is very clever. |

|

If anonymous talk, it's for the birds. Who writes something interesting, should be proud to have his name on it. If they intentionally hide their name, that makes it easier to disappear after writing nonsense, and start over with the next fake name. |

Mistakes

Overheating. Yes we all know, that is not good. Let me explain the meaning of 5V +/-5%, when the data sheet writes so. To understand that, just look at those questions:

- Question: What happens of you exceed this with more than 5%?

Answer: Lifetime is reduced below minimum. - Question:What happens of you exceed this with exactly 5%?

Answer: Lifetime will be the minimum guaranteed value. If that suits you, it's fine. - Question: How to achieve highest possible lifetime?

WIth the above two informations, try to answer this yourself.

Under heating. It says in the data sheet 5V +/- 5%, under heating will also cause defects. So, -6% is not possible, otherwise the data sheet would have said so. At under heating, the tube will give up on you, much sooner as with over heating. The difference with over heating is, problems with under heating come a lot faster, and heavier, somewhere at or below 500 hours.

With under heating, the tubes however will often recover for the greater part of it, when heater voltage is corrected. Whereas with overheating damage is permanent.

This is the reason, why heater voltage tolerance is always written so clearly in the data sheet, at it's first page, in a large box.

Slow start of heaters. Actually this ok, BUT..... only if there is no anode current. If you never heard about this requirement, don't ask other amateurs. Better ask specialists, like those who build tubes, for instance.

In just a few lines: The best was to blast off active spots from the heater, is FORCE full current at a half warm heater. That really works well, because particularly at those positions of the heater which are better as the rest, current density becomes too high. Some powder-like pieces will blast off, ending the emission of those spots.

Note, switch off abruptly is JUST AS bad, and the reason for unexplained heater breakage. But many of those module makers never heard of this. They do their 'great job' in slow start, But then, stupidly, when it comes to slow ramp down, which would be SO EXCELLENT (provided anode current is off), they never heard of it, and just switch off the whole unit off: Bang! So the heater cools down fast, and breaks one day.

This page is about Errorz and Misstakes. Here is another one:

Just cut and past that in the Google Earth search: 32°40'33.94''N 117° 9'27.84''W